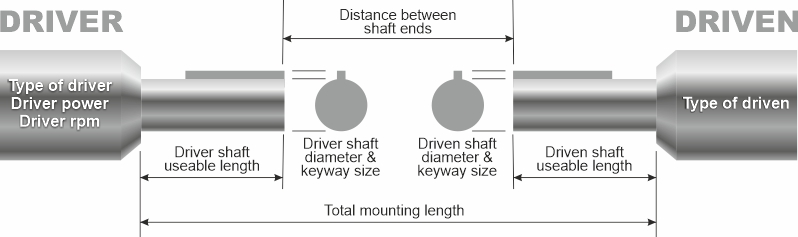

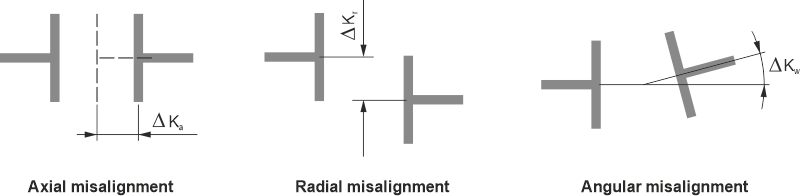

If you need a mechanical power transmission coupling, the device used to connect facing ends of two shafts together or flange to shaft to transmit mechanical power from the driver to the driven, there are two main options. Rigid shaft couplings are used in applications where the two shafts are more precisely aligned, but flexible shaft couplings allow for issues such as angular, axial and parallel misalignment which are more common in many industrial applications.

Flexible shaft couplings are designed to relieve the effects of mechanical power transmission shaft misalignment. Rigid shaft couplings are able to transmit higher torque than flexible shaft couplings, due to the cushioning effect of flexible coupling elements adsorbing some of the torque when using flexible shaft couplings.

Read and download the guide to correct coupling selection for your application found via this link: selecting-the-correct-coupling

jbj Techniques hold in stock a wide range of mechanical power transmission coupling types in a wide range of sizes for quick despatch. jbj Techniques also have the technical expertise to assist you in the specification of the best coupling for your needs and extensive machine shop services, all in-house to enable prompt despatch of those more bespoke couplings, large or small in size and quantity.

We offer a wide range of high-quality mechanical and fluid power products, readily available from our extensively stocked warehouse. But we’re more than just a supplier - whether you need a single drive component or a complete driveline solution, our knowledgeable sales team is here to help. We tailor recommendations to suit your specific application. Thanks to our strong inventory and fully equipped in-house machining facilities, we also ensure fast delivery times, even for custom mechanical power transmission couplings.