For coupling fatigue torque: TKW = 0.15 x TKN, where TN > TW must be adhered to.

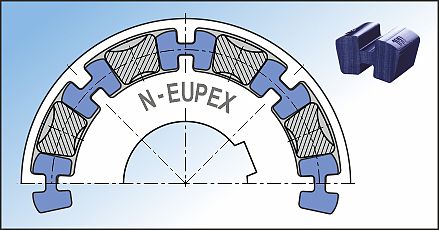

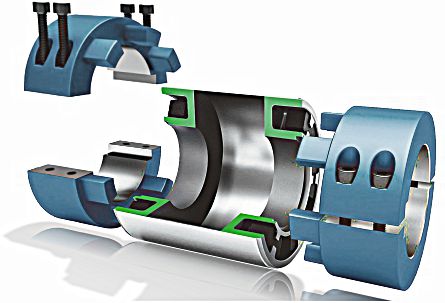

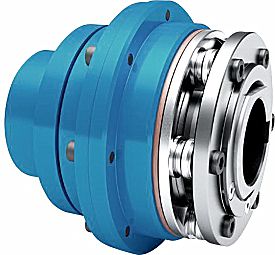

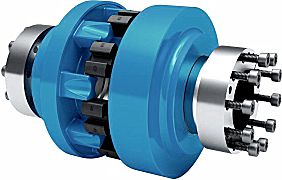

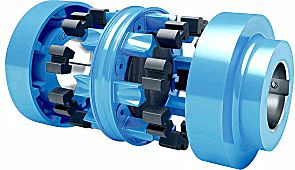

FLENDER has succeeded in increasing both the performance and the bore capacity of the entire N-EUPEX series by nearly one-third. As a result, users benefit from greater torque, higher rotation speeds and a change in size. The N-EUPEX series has proven itself for decades as a standard solution, and it has now been elevated to a new level of connector technology.

The name "EUPEX" comes from ancient Greek and means "well connected." These couplings by Flender GmbH are as durable as the ancient Greek name is old. The manufacturer of gear units, couplings, generators and complete drive systems has been producing the EUPEX coupling for about one hundred years, ever since the company's founder, Alfred Friedrich Flender, had this name entered as a trademark in the registry of the Patent Office of the German Reich on December 22, 1923.

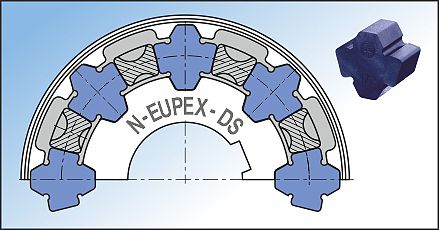

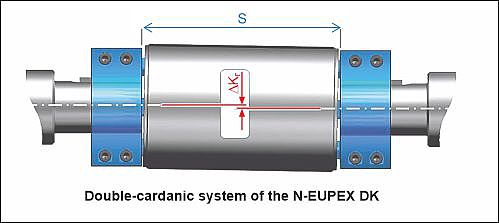

The successor to these couplings, N-EUPEX®, has been manufactured since 1967 and there are millions of them all over the world in every industrial sector. To continue to meet the high expectations for the product in the coming decades as well, the development team has made some changes to the series. New types were added to the modular principle of N-EUPEX. Couplings with a torque limiter, with a clamping element as well as with a short double-cardanic design will now be added to the existing short and long types. In addition, elastomers made of TPU are offered. Moreover, both the performance and the bore capacity were increased for all types in the series in 2020.

The pages via this

»

link « contain detailed information and the advantages regarding these changes and here below, in brief, are a few notes