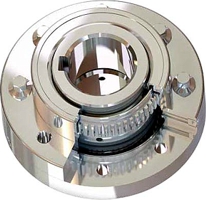

The new generation of the Gear Coupling. By incorporating the latest advances in Finite Element Analysis technology, Lovejoy has revolutionized this type of torsionally rigid coupling. Increased nominal torque, larger maximum bore size and longer service life are just a few of the many advantages of the HercuFlex® coupling. Despite the advanced nature of these improvements, the HercuFlex® Gear Coupling still utilizes the standard AGMA flange interface to ensure field interchangeability.

Gear couplings are the foremost coupling type. They can do things that many other coupling types are unable to perform, or that need expensive modifications and derating to function. Gear couplings have the highest power density, offer more variations, a wider size, torque, and bore capacity than any other coupling type. They are easily modified for shear pin service, floating shaft type, vertical applications, electrical isolation, limited end float, and can have a brake drum or disc added. While some features may be available on other couplings, it is typically easier and cost effective to modify a gear coupling. With all these advantages, the gear coupling is used on more applications versus the nearest competing coupling type.