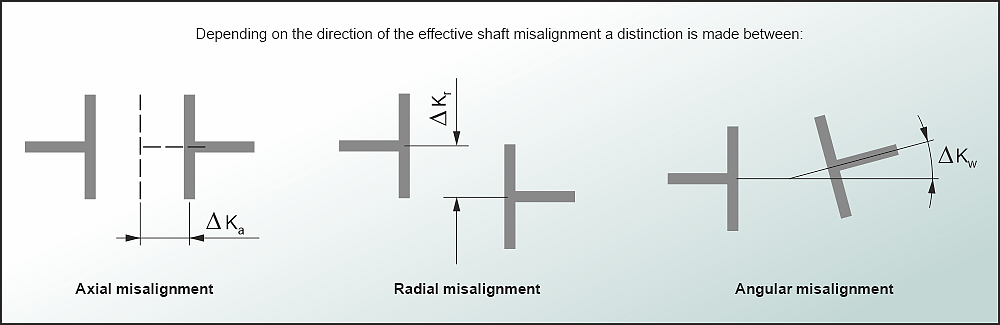

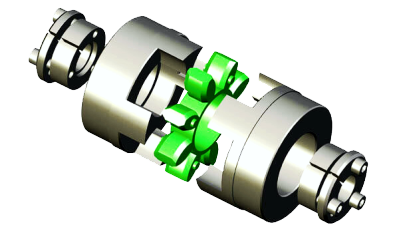

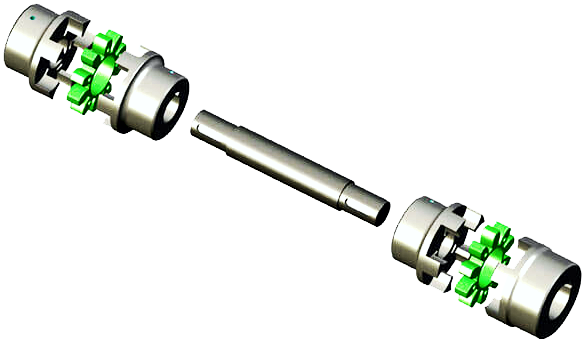

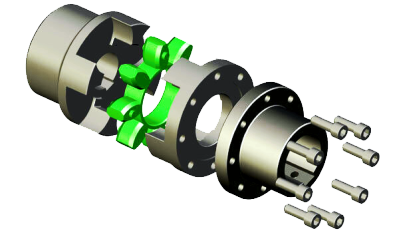

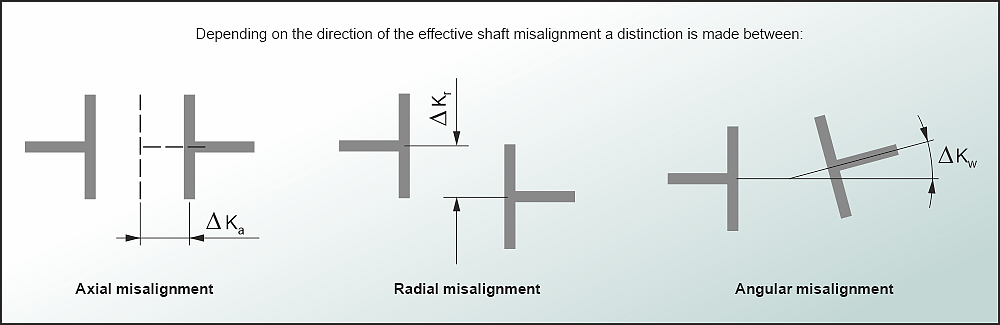

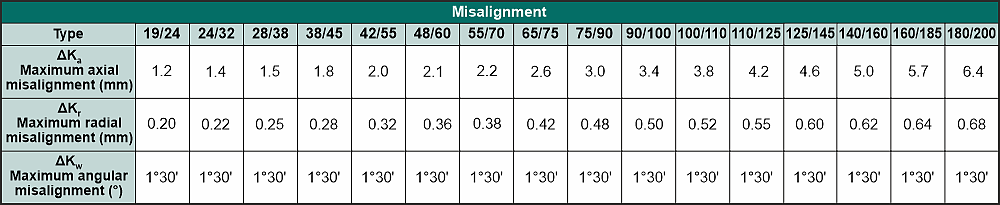

Due to the complete

flexibility and

ductility of the elastomer ring, it

compensates for parallel and angular

displacements as well as to

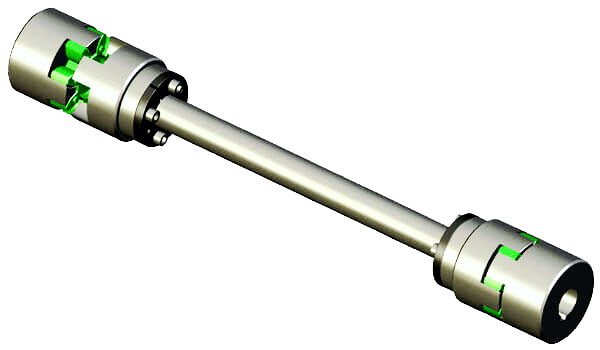

absorb longitudinal movement of the shafts.

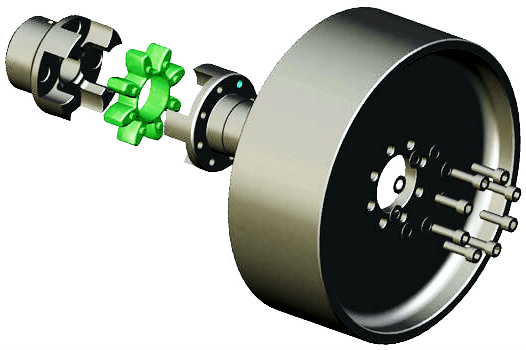

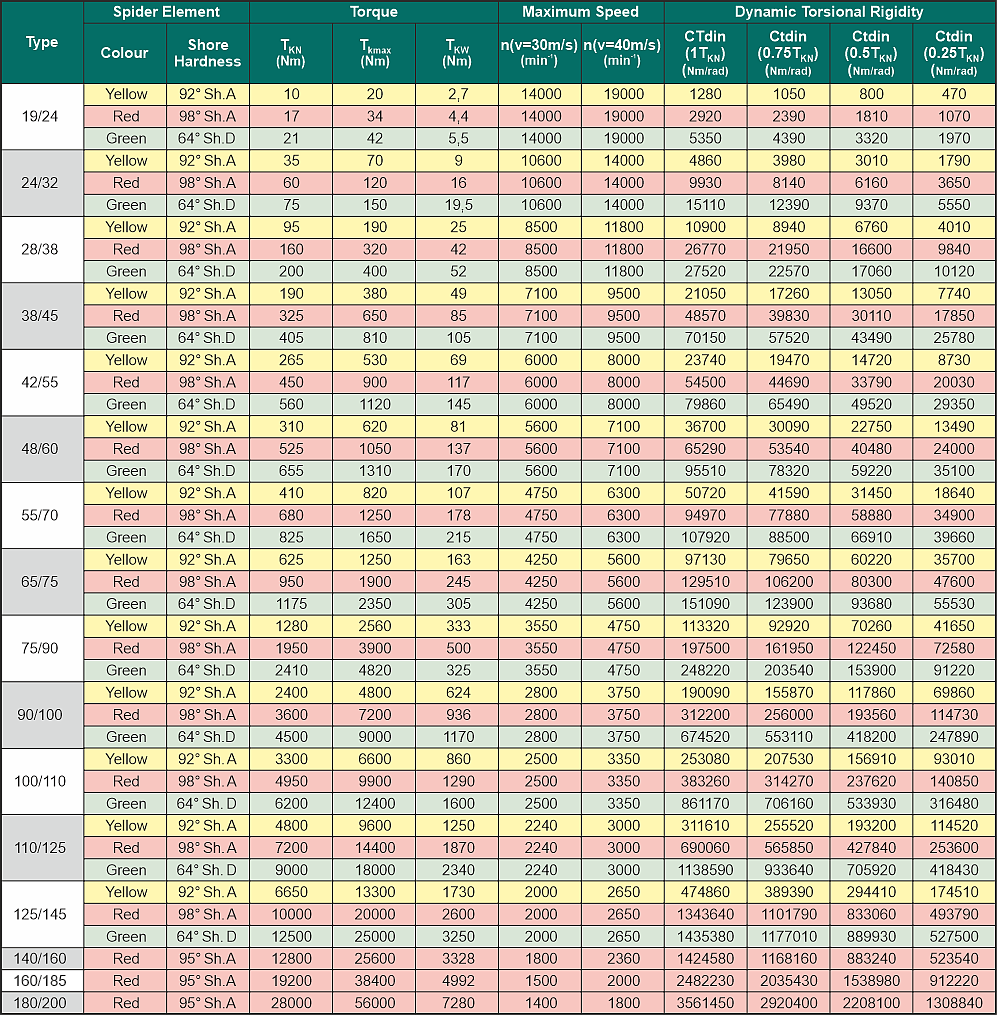

Manufactured in the UK to jbj Techniques' proprietary patterns, G Series jaw couplings are expertly gravity die-cast using LM25 aluminium alloy. This process ensures robust and durable castings with superior strength and reliability. Unlike injection-cast alternatives, which are prone to porosity and compromised structural integrity, gravity die-casting produces components of consistently high quality, designed to perform under demanding conditions.

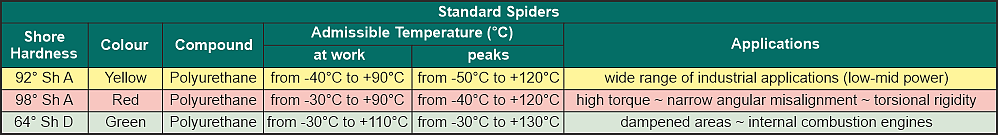

Each coupling is precision-machined finished at jbj’s well equipped machine shop facility to meet specific customer application requirements. Combined with the correct Shore hardness elastomer element, these jaw couplings are ready to efficiently transmit mechanical power across a wide range of machinery applications.

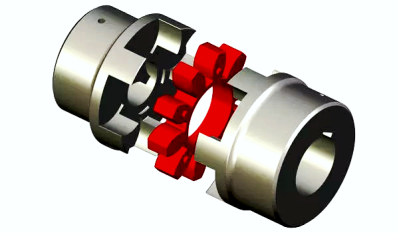

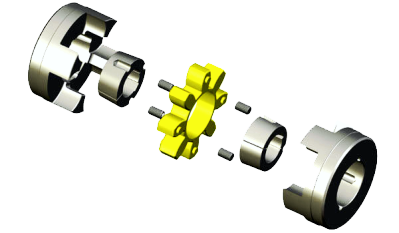

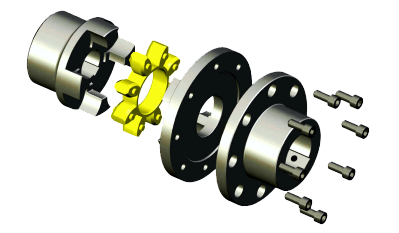

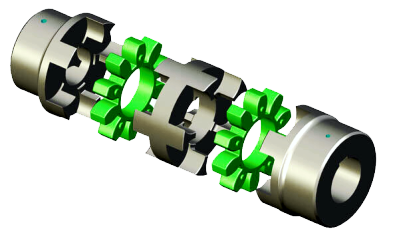

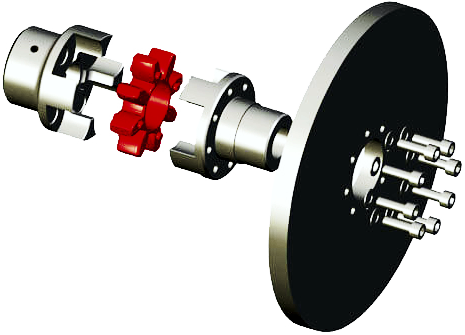

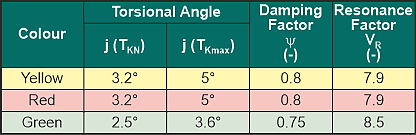

The involute teeth of the elastomeric inserts are crowned in order to avoid edge pressure on the tooth flanks and so avoid undesirable axial thrust. The puncture proof spider coupling can be loaded extremely high since the elastic elements are submitted to compression and not to bending moments of force. The elastomer gear ring, made of a newly developed polyurethane of various degrees of shore hardness, has important advantages in comparison with the standard polyurethanes. It is non-ageing, with resistance against hydrolysis (can be used in tropical conditions), non-abrasive, has a high self-damping effect and is also

resistant to oil and ozone. It can be used with temperatures ranging from

-40°C to +120°C.

Spider / jaw mechanical power transmission couplings can be used for horizontal as well as for vertical shaft connections, for reversing, intermittent service and are electrically insulating. The operating characteristics and the durability of the coupling are very positively influenced by the high overall precision of the machining, especially the claws, unbalance is reduced to a minimum, running is improved and service life considerably increased.

Scroll down this page for

specification catalogues (link) for straight jaw spider couplings and jaw in-shear type couplings.