When designing a new hydraulic system for your project there are basic requirements for the selection of a suitable splitter gearbox, here is a quick overview of each one.

1) POWER, the rate of transfer of energy.The first consideration must be the hydraulic needs of the machine you are designing, the required maximum flow rate and pressure for each hydraulic circuit, (will all circuits be operating at the same time, differing loads etc), with this information you will be able to determine the number of gearbox output points, shaft power demand for each hydraulic pump and therefore the total required system power then, considering efficiencies you will be able to define the total power requirement for your prime mover. Typically, this will be a Diesel engine for most mobile applications however electric motors can be used, we will be happy to discuss the system at this stage and advise on power calculations.

2) PRIME MOVER, a machine that converts potential energy into mechanical energy.With the prime mover power defined, a suitable engine or motor can be investigated with consideration given to the required speed. Splitter gearboxes can be supplied with speed reducing or speed increasing ratios so pump speed can be fine tuned to an ideal input speed. With this information to hand you will be able to decide on your preferred engine or motor and relevant dimensions such as flywheel and flywheel housing sizes or motor frame size, flange and shaft, etc, the chosen supplier will be able to advise details and provide drawings, CAD files, spec sheets etc. We will need to know this information.

3) HYDRAULIC PUMPS, devices converting mechanical energy into flow of oil and pressure.Decide on the make and model codes of the hydraulic pumps you intend to use noting that a splitter gearbox will reverse the direction of rotation to the pump drive shafts, (for splitter gearbox drives, spline pump shafts are preferable), also the required pump driving speed if different to the prime mover selected. With all this information to hand we will be able to calculate the torque demand for each pump, total for the gearbox and drive coupling and consider gearbox options.

4) SERVICE FACTOR, multiplier used for defining expected gear or bearing life.Selection of a suitable splitter gearbox will typically begin with the maximum torque that will be applied under the harshest operational conditions multiplied by a suitable service factor. The value of this factor is defined based on the type of application, expected run time, required operational life, importance of the of the equipment, number of engine cylinders and application specific conditions. The application of a service factor effectively over sizes the gearbox in order for it to operate for a healthy number of hours. Service factors may also be referred to as life factors.

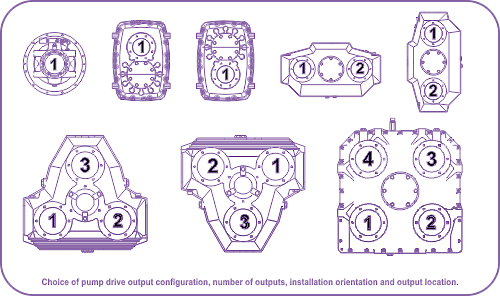

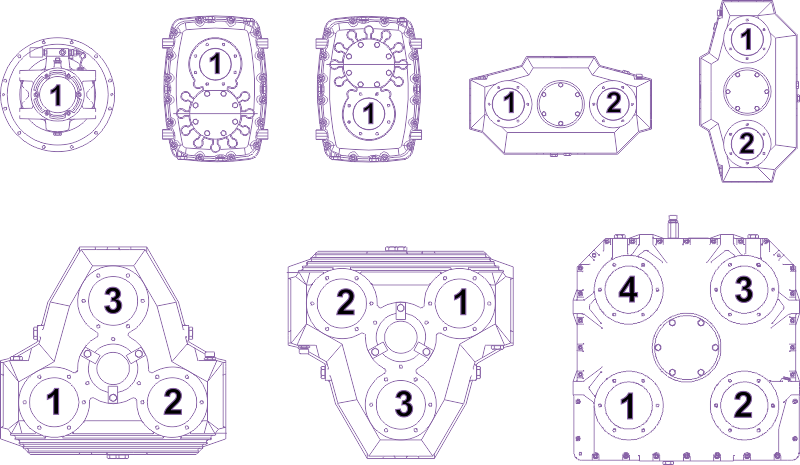

5) DIMENSIONS, fundamental quantities used to define physical details.It is important to check the physical size of the proposed gearbox with particular attention being paid to the position of the pump drive locations. This is to make sure it will be possible to fit the chosen pumps with suitable clearances, to be able to connect the hydraulic pipes, hoses and any associated control components that may be required. Pumps with rearward facing ports can be useful. We can help here by examining the details using 3D CAD.

6) COOLING, the transfer of thermal energy from a hot object to a cooler one.The power and speed transmitted by drive systems has a direct relationship to drive torque, or to put it another way the physical strength of the drive. Another power figure relative to drive system selection relates to thermal capacity. This value defines the ability of the drive to dissipate heat by radiation from its various surfaces. During operation, heat is generated by the action of friction between the surfaces of bearings and gears. This heat is absorbed by the oil in the gearbox and transferred to the external surfaces. The amount of heat the surfaces can dissipate is expressed as a power figure, often lower than the power figure used to calculate gearbox torque capability. Providing the surfaces are able to fully dissipate this heat all will be well. However, in some instances the thermal input power may be greater with the undesirable effect of the gearbox oil over heating. Fortunately we can use the oil to remove the excess heat that the gearbox surface cannot, by pumping it out of the gearbox and passing it through a

heat exchanger, with the option of passing it through a filter before returning it to the gearbox. With these details already provided, we will be able to advise a suitable oil flow rate and dissipation value. With some additional information on the cooling medium, usually air or water, temperature flow rates, etc. we will be able to specify a suitable heat exchanger from our product range.

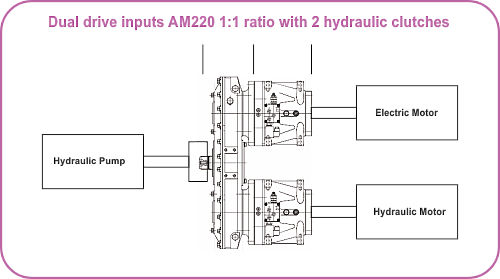

Depending on the drive design there may be additional requirements, usually we are able to cover most eventualities, for instance non-standard pump mounting arrangements, clutch between engine and drive, non-standard engine sizes, Nema frame electric motors, high inertia differences requiring torsional vibration calculations, varying operating conditions such as exhaust gas regen cycles, pump seal failure witness drains. Gearbox reversal and use as a combiner, (multiple input single output), hybrid drives, solid output shafts enabling the use of cardan drive shafts giving the option for greater centre distances and so on. With over 200 years of combined accumulated gearbox knowledge and experience, jbj Techniques Limited will be able to help to correctly define and supply a suitable drive system for your project.

jbj Techniques Limited has available for you a tremendous variety of single and multiple power take-offs and gearboxes – each of which can be used as a pump drive for many different tasks.

Whether you need a single or multiple pump drive for use in a mobile application, through to large heavy plant vehicles, or you’re designing a new piping and liquid flow system for an industrial manufacturing plant, you can find the right jbj Techniques Limited product for your needs. So take another look at this guide now, and think about how you can choose the proper pump drives for your next project.

Don't forget, you are not alone, jbj Techniques Limited are here to help! If you have more questions about selecting the drive unit that’s right for you, contact jbj Techniques, email:

info@jbj.co.uk, telephone:

+44 (0)1737 767493.