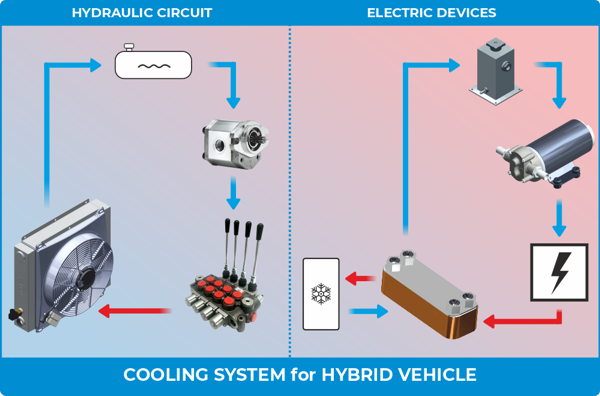

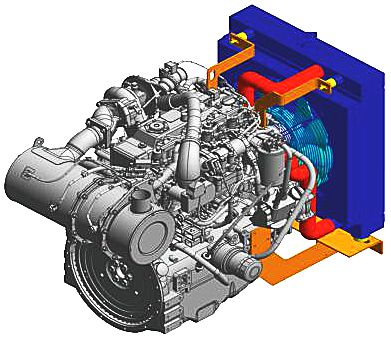

Electric vehicle batteries running too hot?

jbj Techniques have the answer. We can take your EV battery cooling requirement and turn it into a reality. Complete autonomous systems that can be used in conjunction with the vehicle air conditioning circuit. Power saving fan drives to reduce the draw on the EV battery pack. We can take your cooling requirements from concept through to the finished package

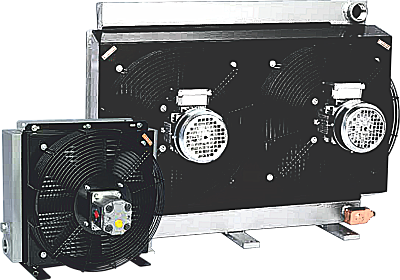

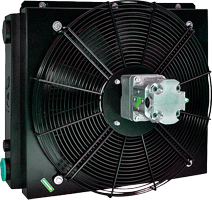

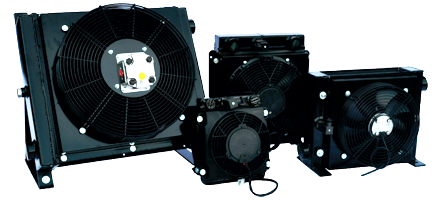

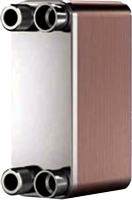

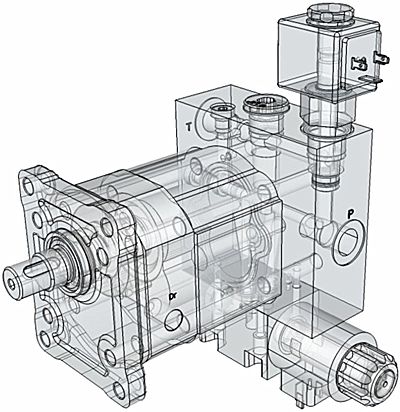

Hydraulic system running too hot?

jbj Techniques have the answer. In line coolers or offline coolers available from our extensive range.

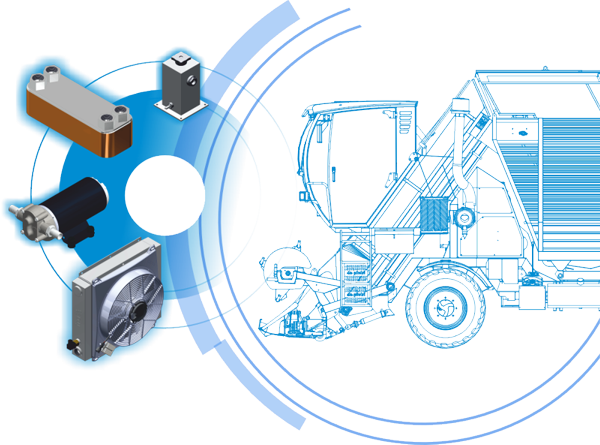

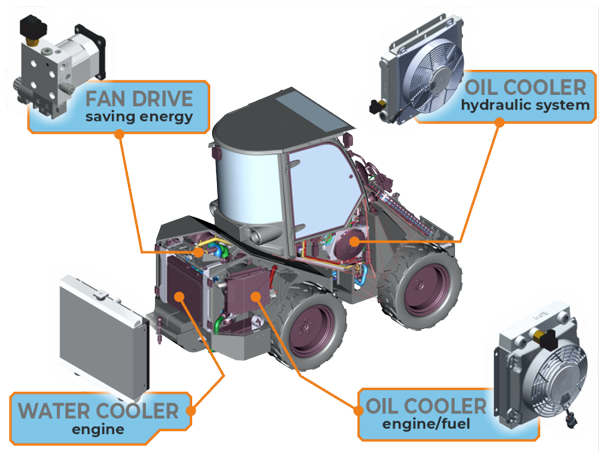

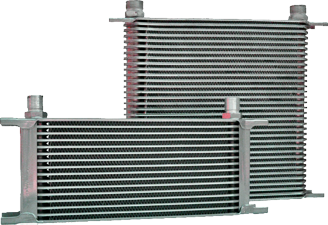

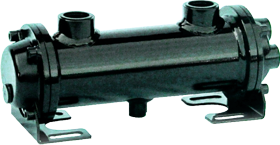

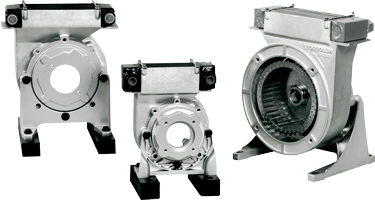

Need to cool your diesel or petrol engine, intercooler or gearbox oil?

jbj Techniques have the answer. For machine manufacturers requiring improved performance or combined cooling of multiple media in a compact design or different cooler area footprint.