Mechanical power take-off units

Consist of a complete clutch assembly with shaft and bearings mounted in a cast-iron housing for easy engine installation.

Available in sizes up to 533 mm (SAE 21), these mechanical PTOs are ideal for many basic actuation installations.

Remotely actuated versions are available for safer, easier operation and greater equipment design flexibility.

An extra margin of strength

Actual design torque capacity of the clutches used in these power take-offs is in excess of the power rating listed. This permits the power take-offs in proper adjustment to withstand temporary torque overloads. Rated torque can be transmitted while moderately slipping during short periods without permanent damage.

Specifications

» Suitable for Duty Class II industrial applications with internal combustion engines up to 1243 kW (1667 hp) and with standard SAE flywheel housing dimensions from No. 6 through No. 00.

» Contain clutches ranging in size from one plate SAE 6.5 to one plate SAE 14; in two-plate size from SAE 11.5 to SAE 18; and three-plate size from SAE 11.5 to SAE 21.

» Standard sealed pilot ball or roller bearings eliminate the lubrication requirement and shaft rifle-drilling normally encountered with standard pilot bearings. Also available as options: ball bearing throw-out collars and finger springs.

» kW/horsepower and torque capacities listed can be increased by the use of sintered-iron clutch plates, which are available as optional equipment in the SAE 8 through SAE 21 sizes.

» All bearings, shafts and other parts are designed with liberal safety factors to maximize life under normal operating conditions.

*

* To avoid overloading the shaft and bearings, use the allowable side-pull load data in this bulletin, and calculate the side load. The resultant value should be less than the corresponding maximum value listed for each power take-off.

For assistance please contact jbj Techniques Limited technical office, telephone:

+44 (0)1737 767493 or email:

info@jbj.co.ukSpecial power take-offs are available. These include the innovative straddle bearing concept and a limited-attendance PTO that contains a positive throw-out collar clearance mechanism and extended lubrication intervals. For original equipment manufacturers, special power take-off units can be designed to meet individual requirements when sufficient volume is indicated. Design variations can range from minor changes to entirely new concepts.

How To Choose The Appropriate PTO

Several factors must be considered in the selection process in addition to duty service, such as:

SPEED LIMITS • SIDE-LOAD LIMITS • CLUTCH TORQUE LIMITS

The selections are usual dry clutch disconnect type applications where engagements are infrequent and are at low (idle) input speed. Once engaged operation continues for one hour or more, engaging the clutch at higher input speed will reduce component life. Refer to the following duty classifications and examples.

Application Data:

SAE Housing Size

SAE Flywheel Size

Number of Engagements

Pulley Pitch Diameter

Pilot Bearing Diameter

Input Power to Clutch

Input Torque to Clutch

Maximum Output Shaft RPM

Load Centre-line "X" Dimension (side-load applications)

Determine duty classification

(page 5)

PTO Selection Procedure

1. Calculate NET Input Power or Torque to PTO

2. Calculate imposed side-load using the following formula (side-load only):

(metric) L =

1945010 x kW x F x LF

N x D(imperial) L =

126,000 x HP x F x LFN x DL = Actual Applied Load kg (lbs)

N = Shaft Speed (rpm)

D = Pulley Pitch Diameter mm (in)

F = Load Factor

1.0 for Chain / Gear Drive

1.5 for Timing Belts

2.5 for All V Belts

3.5 for Flat Belts

LF = 2.1 for reciprocating compressors and other ‘severe shock drives’ and 1.8 for ‘large inertia type drives’ (crushers, chippers, planers, etc.)

3. Use the PTO rating table on

page 6 and the side-load tables on

pages 7 and

8 with the following information:

» NET input power or torque to clutch.

» SAE flywheel size.

» SAE housing size.

» maximum PTO output shaft speed.

» calculated side-load (side-load applications).

Find proper duty class along top row and SAE housing & flywheel size along left-hand column of the rating table on

page 6.

A PTO that has a power or torque rating greater than the calculated application power or torque rating is suitable for the application.

The PTO output shaft speed should be at or under the listed ratings for the drive rings.

Use PTO output shaft speed and calculated side-load and refer to tables on

pages 7 and

8 to verify that the side-load is at or under the load at the given speed.

PTO sizing calculation example and

ordering code example.

Links to the mechanical PTOs:1 »

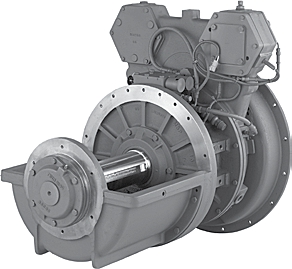

SP series:

Standard PTO line, up to 11388.87 Nm (8,400 ft-lb). Straddle bearing housing available.

2 »

CA series:

Standard in-line, up to 298.28 kW (400 hp).

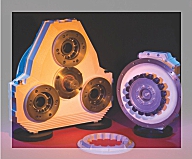

3 »

C(X) series:

Standard, available in sizes 6.5" to 11.5".

4 »

SL series:

Spring loaded clutch, 11.5" to 14".

5 »

TC series:

Spring loaded automotive style 13" clutch.

6 »

IB series:

Heavy duty PTO line. Ventilated plates and drive rings. Up to 11388.87 Nm (8,400 ft-lb).

7 »

RB series:

Rubber block drive, no clutch disconnect, 11" single row, 14" double row.