These hydraulic gear pumps and motors can work under heavy duty operating conditions and transmit high hydraulic power, feature good hydraulic, mechanical and volumetric efficiency, low noise level and, last but not least, compact dimensions and low weight to power ratio. Ideal for both industrial and mobile industry sectors.

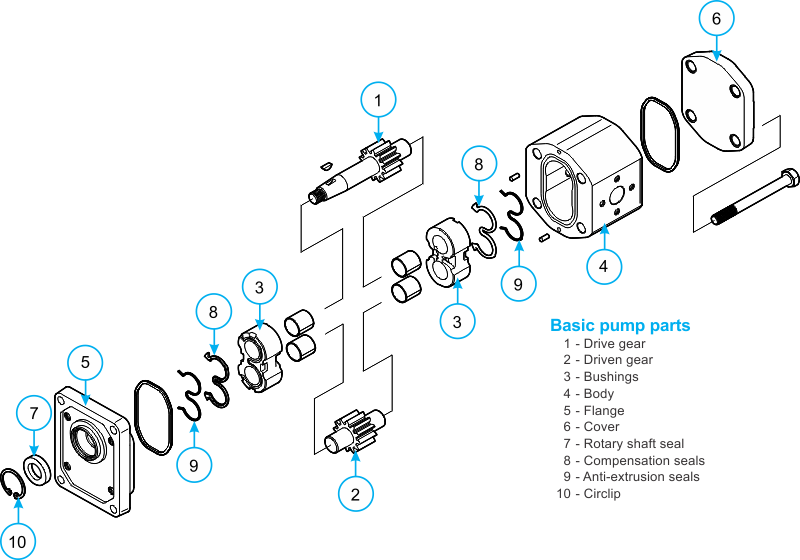

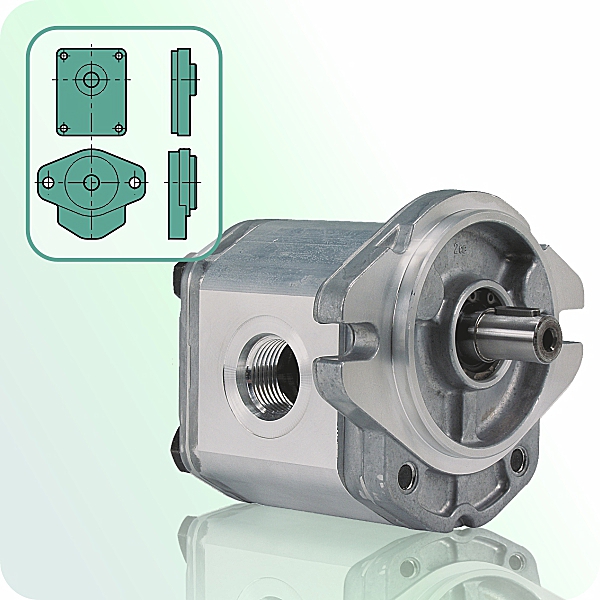

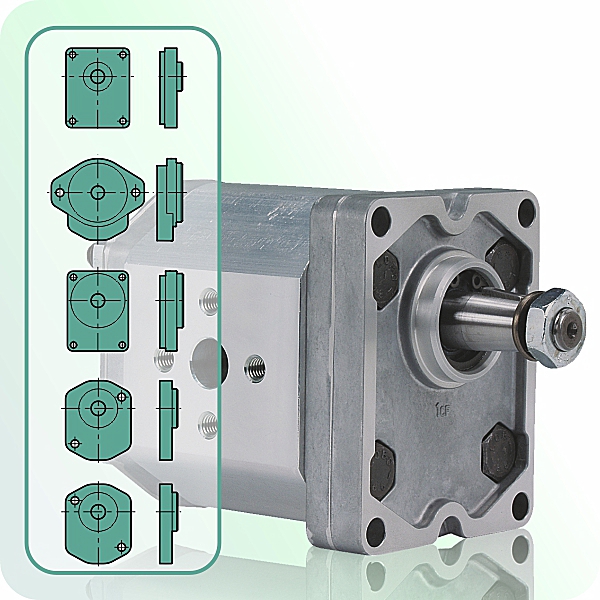

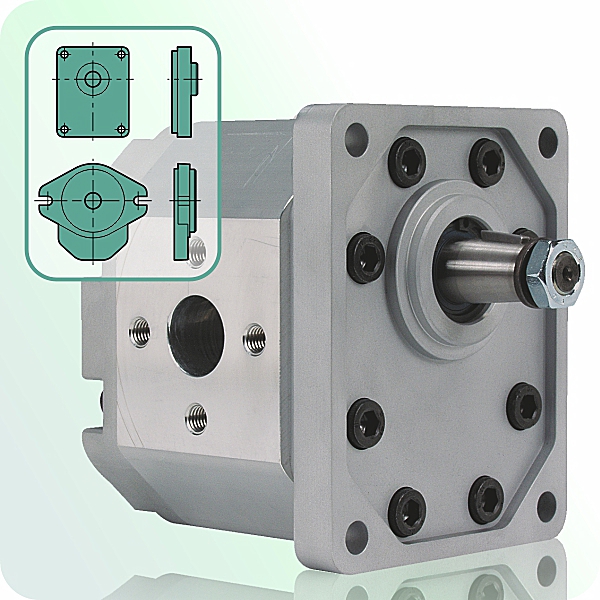

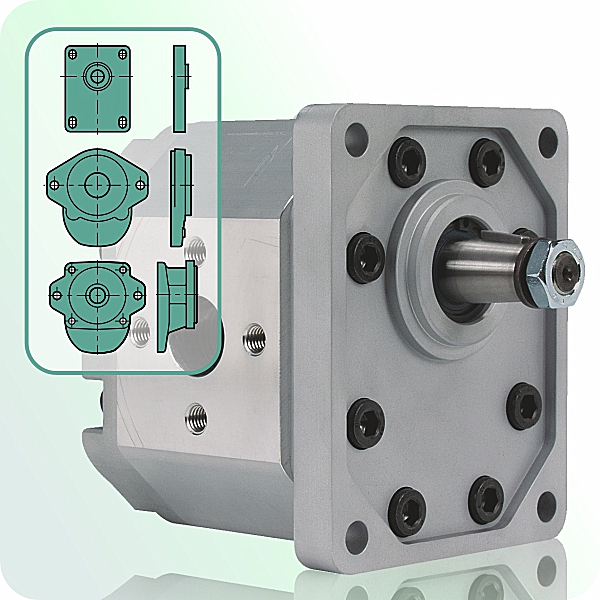

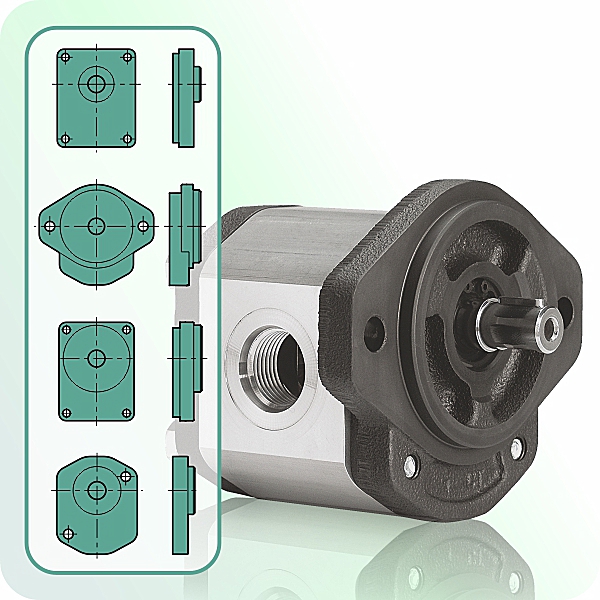

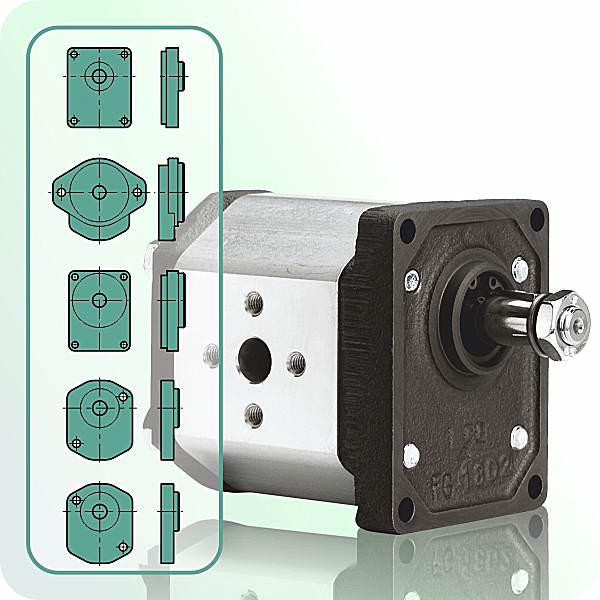

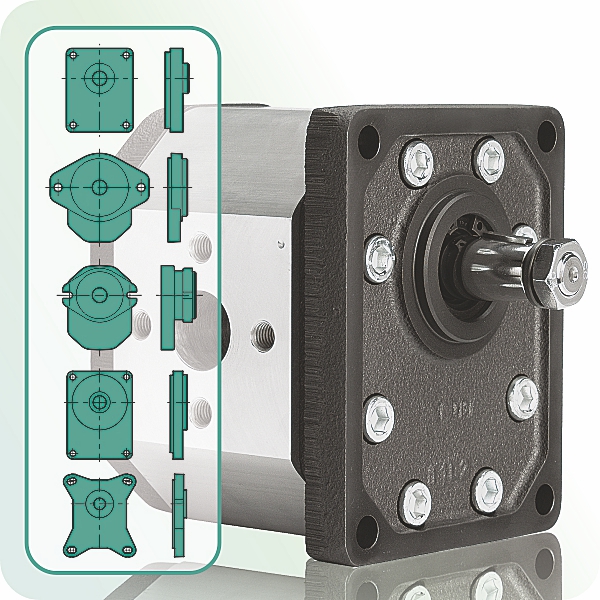

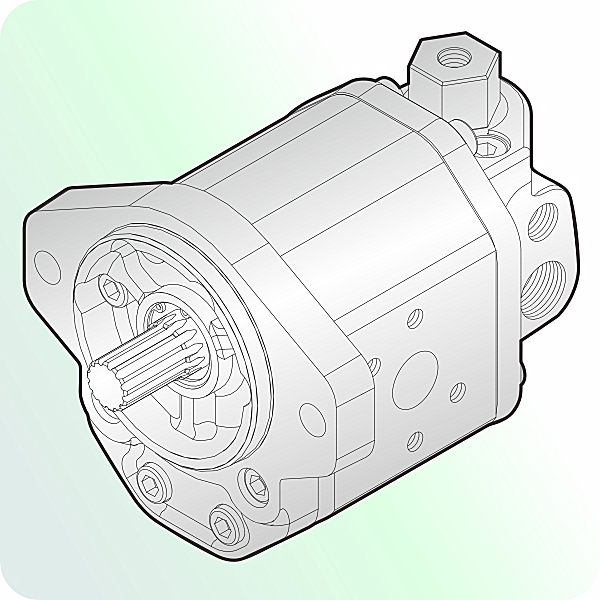

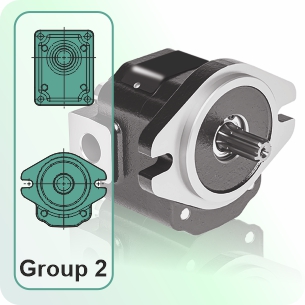

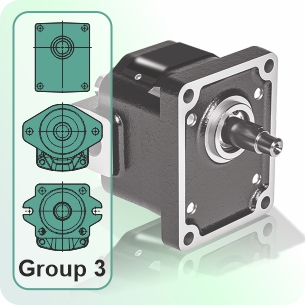

The basic components consist of a gear set supported by two aluminum bushings, a body, a securing flange and a cover.

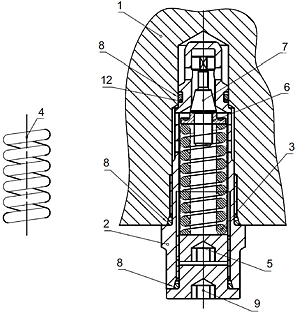

The shaft of the driving gear projecting beyond the flange mounts a seal ring coupled with a metallic ring to strengthen the setup. Both rings are held in place by an elastic securing ring.

The body is made of a special aluminium alloy with high strength for minimized deformation even when subject to high pressure. There are also

cast iron bodied pumps and motors now available for applications requiring high pressures, optimal performance and endurance. Flange and cover are made out of cast iron or aluminium alloy, depending on the model series type, manufactured through a process of continuous flow casting and with a final surface treatment of phosphating.

Gears are made of special grade steel. Their manufacturing process includes case-hardening and quench hardening. The gears are ground and fine finished to achieve a high degree of surface finishing. Good tooth profile design and geometric proportions ensure low pulsation levels and low noise levels during motor operation.

Bushings are made of special low-friction and high-resistant aluminium alloy and manufactured from die-casting that have excellent high strength and anti-friction characteristics. Also equipped with anti-friction DU bearings with tight tolerance.

Special and symmetric compensation zones onto bushings, insulated by special preformed seals with special anti-extrusion ring, allow full free axial and radial movement to the bushings, which is proportional to motor operating pressure. In this way, internal leakage is dramatically reduced, ensuring very good pump performance (both in terms of mechanical and total efficiencies) and proper lubrication of pump moving parts.