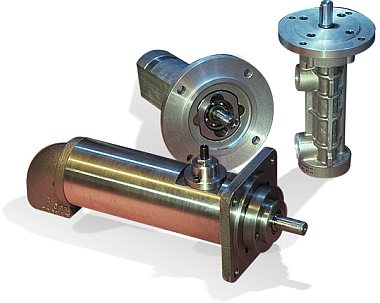

» Screw pump flow rates up to 5.400 lpm, larger flow rates are available upon request.

» Pressure up to 200 bar, higher pressure versions are available upon request.

» Suitable for lube oils (mineral and synthetic – even at high viscosity > 100.000 cSt, HFC fluids, water based emulsions, cutting oils, aeronautic and dielectrical fluids, LFO and HFO, silicon fluids).

» Execution conform to API 676 (latest edition).

» ATEX compliant

» Built in

relief valve

, optional.

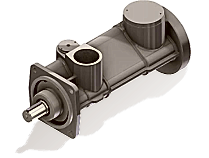

» Lubricating system for: speed variators, turbines, gearboxes, papermill machines, hot forming machines.

» Lubrication system for the petrochemical, iron and steel, and mining industries as well as shipbuilding.

» Machine tools, bed traversing.

» Hydraulic presses.

» Hydraulic units for elevators.

» Hydraulic supporting.

» Rolling mills.

» Test benches.

» Sheet metal machines.

» Plastic molding machines.

» Medical Units.

» Cooling Lubrication: deep hole drilling, pipe boring, chip conveyors.

» Filtering: mobile filtering systems, off-line filtering systems for process machines and machine tools, hydrualic presses, textile machines, grinding machines.

» Heat Exchanging: injectors heating for plastic molding machines, heat exchangers.

» Flushing and Boosting: piping systems washing, hydraulic systems flushing, boost circuits.

» Hydraulic oils.

» Lubricating oils.

» Diathermic oils.

» Oil-in-water emulsions (min. oil percentage 5%).

» Light and heavy fuel oils.

» Phosphoric esters.

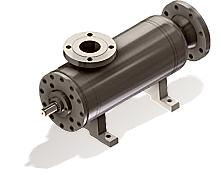

» Compatible with a wide range of viscosities from 1 to 12,000 cSt and above.

» Efficiently working also at very low temperatures (-20°C).

» High self-priming capacity.

» High rotation rates = minimizing the size and cost of the pump.

» Steady flow rate = maximum efficiency in heat exchange applications.

» Special design for systems with entrained air in the lubricant = minimizing the vibrations and noise caused by air.

» Minimum sensitivity to particle pollution = longest life of the pump and circuit.

» Continuous operating pressures up to 130 bar, peak 200 bar.

» Pulsation-free = maximum efficiency of filtering applications.

» Extremely quiet.