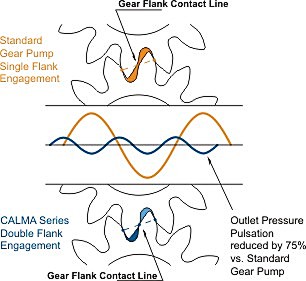

The pump, designated CALMA, features a newly engineered tooth geometry, innovative true dual-flank gear engagement, reduced trapped oil volume and advanced trapped oil management. The design reduces pressure pulsation by 75%, which is the key factor determining the pump's noise levels, while also reducing energy consumption.

In the market for electric and gas-powered vehicles, low noise is a key requirement, while low-speed operation enables improved control and positioning for various vehicle functions. Consequently, gear pumps that can operate efficiently and quietly at low speeds are now among the most important priorities for electric vehicle designers. The trend towards lower noise standards, which has been further encouraged by legislation in Europe and elsewhere, also applies to other markets including truck, bus and off-highway, where CALMA is also expected to find many applications.

Apart from its low noise benefits, the CALMA pump offers important energy-saving advantages. Considerable excess hydraulic flow is generated in maneuvring the vehicle and this energy is normally dumped via valves, creating waste heat and a premature drain on battery power. CALMA's adjustable and low-speed capability avoid unnecessary power drain and further increase battery life.

Both static and in-vehicle tests have demonstrated that CALMA series pumps offer significantly lower noise operation when compared with other external gear pumps. In many cases, they can also match or even out-perform more expensive internal gear pumps on efficiency and low-noise operation. CALMA is especially well suited to applications on electric counterbalanced lift trucks and warehouse lift trucks.

Sound power testing in comparison with other quiet gear pumps on these vehicles showed CALMA provided significant reductions in noise during the steer, tilt and lift functions by 50% to 85%. CALMA is also well suited to electric aerial work platforms and other mobile equipment where low noise, low speed and high efficiency are required.

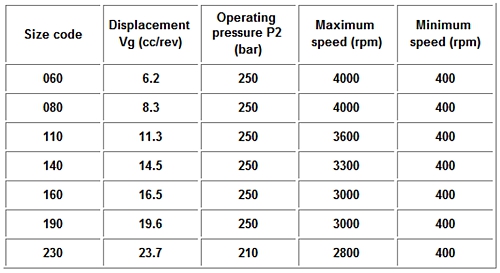

Following an exhaustive program of research and development in collaboration with the University of Dresden, Haldex Hydraulics has introduced a range of CALMA pumps in displacements from 6.2 cc to 23.7 cc. The company is a specialist in hydraulic gear product technology and established itself as a leader in low-noise gear products a decade ago when it introduced the first WQ series (quiet) gear pump product line. This introduced the concept of true dual flank engagement of the gear teeth (as opposed to “almost dual flank engagement”), which is unique to Haldex and which reduces the amplitude of the pressure pulsations introduced into the hydraulic system.

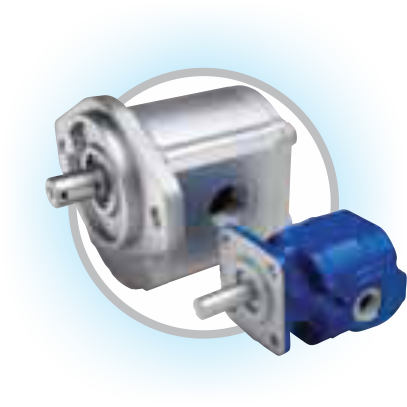

Like other products in the Haldex range, the new CALMA pump is designed to be used as a single unit or as an element within multiple hydraulic assemblies. The modular philosophy common to the Haldex range means that standard housings can easily be varied to incorporate different functions and different internal connections. The modular approach also helps to ensure the very exacting production standards required to deliver market-leading technologies cost-efficiently.