The Pump/Motor units consist of a 12/24/48 V, DC motor in the range of 1,5 kW to 4,5 kW and a

W series gear pump with displacement 0,8 cm3 to 31 cm3 /rev. Additionally the units can be equipped with integrated valves and starter solenoids. Concentric Pump/Motor units in difference to

HE power packs are not self-contained and in most cases integrated into an existing system for auxiliary functions, safety functions or support functions. In other applications the pump/motor unit is the power source in the system for lift, move, propel etc.

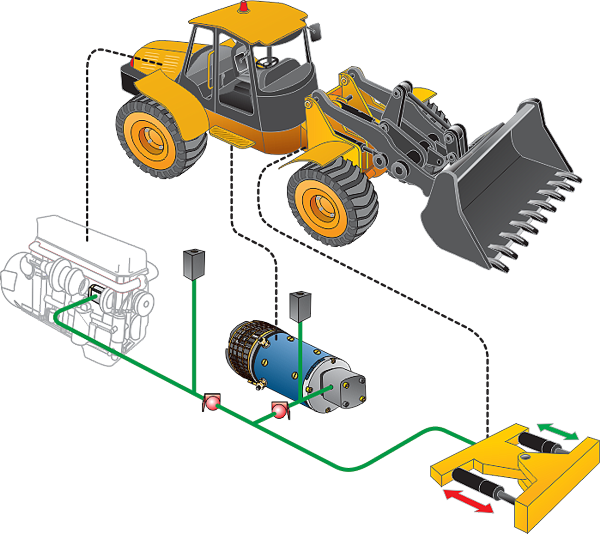

The Wheel Loader has an articulated steering where the vehicle is split into front and rear halves which are connected by a vertical hinge. The front and rear halves are connected with two hydraulic cylinders that change the angle between the front and rear end of the vehicle. The steering is hydraulic and depends on the flow generated by the engine driven pump. If the engine stalls and therefore cannot supply flow for the steering a pressure switch activates the pump/motor unit to supply flow for the steering and by this enable continuously safe maneuvering.

For flow and pressure curves follow this link to

www.jbj.co.uk/e-publications/Concentric-DC-motor-pump-units-from-jbj-Techniques-Limited/3/