Research & development

to constantly improve

driveline technology.

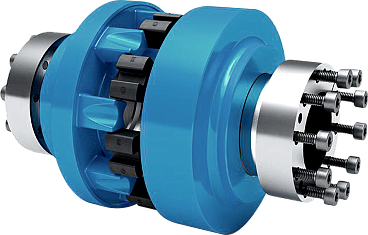

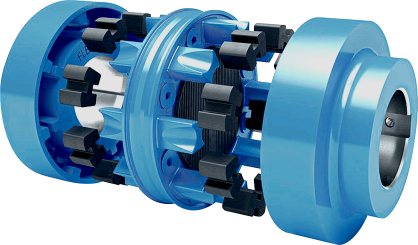

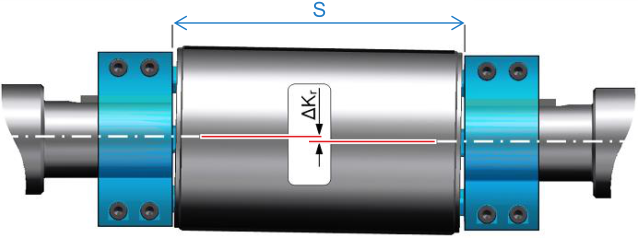

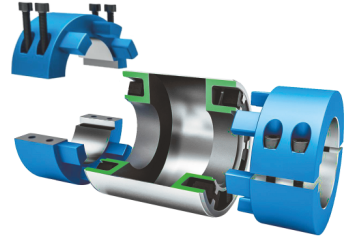

This includes the N-EUPEX® modular system which is continuously growing and, with its detailed solutions, providing users with a wide range of sustainable options for making their machines and systems even more reliable, robust and efficient.

N-EUPEX® rated torque: up to 85,000 Nm,

ATEX Directive for:

II 2G Ex h IIC T6 ... T4 Gb X

II 2D Ex h IIIC T85 °C ... 110 °C Db X

I M2 Ex h Mb X

ATEX Directive for:

II 2G Ex h IIC T6 ... T4 Gb X

II 2D Ex h IIIC T85 °C ... 110 °C Db X

I M2 Ex h Mb X