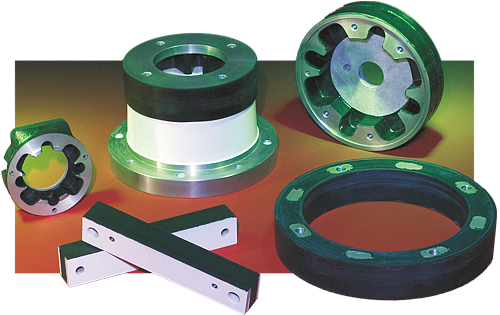

Damping rings for use when vertical mounting (VI-construction) between bellhousing and tank lid or horizontal (B5-construction) mounting position between motor and bellhousing flange.

They consist of two reinforced aluminium rings which are connected by a rubber coat without any metal connection.

The used materials (Nitrile) are resistant against mineral oils and suitable for working temperatures up to +80°C.

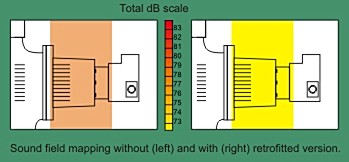

The possible noise reduction will be approx. 3 - 5 db(A).

Damping flanges for use in combination with bellhousings between electric motor and hydraulic pump. These damping flanges of two aluminium parts which are connected by a rubber coat (Nitrile) without any metal connection.

Dampers are resistant against mineral oils and suitable for working temperatures up to +80°C, for short time +100°C.

The possible noise reduction will be approx. 3 - 8 db(A). Damping flanges are available in two degrees of hardness with the description N - normal / H - hard.

Standard bellhousings available on today’s market are generally made of metal. Rising costs have meant that the cast steel originally used has now been replaced by aluminium. To save material, the wall thickness – especially in the case of cast aluminium – has been reduced more and more, with the load level remaining constant.

This reduced wall thickness means that there is only minimal absorption of the noise made by the coupling in the bellhousing. Unlike their cast steel counterparts, the more lightweight aluminium bellhousings have comparatively poor damping characteristics.

The pulsation of hydraulic pumps generates very strong vibrations that are not damped sufficiently by an aluminium bellhousing. Moreover, at rigid bellhousings there is no isolation of mechanical vibration between the electric motor and the hydraulic pump due to the lack of damping characteristics.

Vibration studies have revealed that airborne and structure-borne vibration is at frequencies where human hearing is at its most sensitive.

Under certain unfavourable circumstances, the thin-walled aluminium bellhousing amplifies the running noise of the pump even more; in these cases, the bellhousing resonates in sympathy, similar to a real bell, which can then lead to an additional increase in oscillation amplitude.

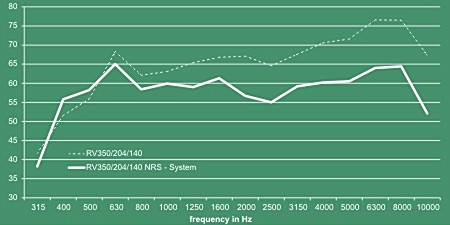

In line with EC Directive "Noise" (2003/10/EG), the planned retrofitting measures are intended to resolve acute problems caused by poor soundproofing and vibration damping, including problems that occur in hydraulic apparatus already in use.The best noise level reductions were achieved using the NRS System.

The NRS System is

» a newly-developed 3D 'High Density' polyester structure.

» tear-proof & temperature-resistant from -40°C to +120°C.

» resistant to most currently available hydraulic oil types.

» easy to fit and 100% recyclable.

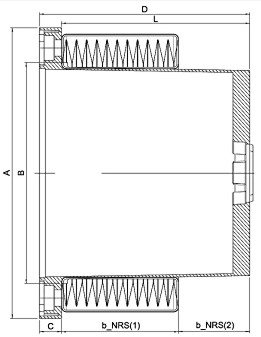

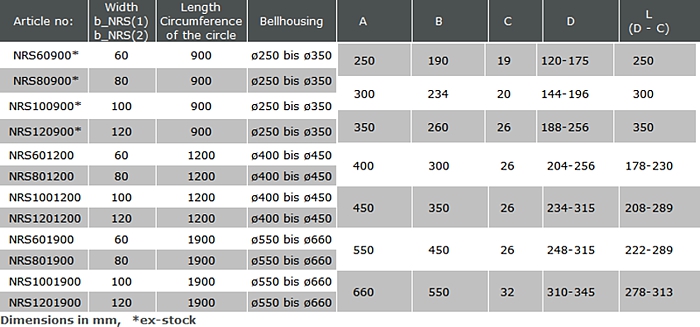

» available in 4 different system widths and 3 lengths for retro-fitting or as original equipment.

With the NRS System, it was possible to reduce the total noise emission level of a cast aluminium bellhousing in critical frequency ranges by more than 10 dB. This reduction is clearly audible to the human ear. The graph shows examples of frequency ranges of a standard cast aluminium bellhousing and a version with NRS.