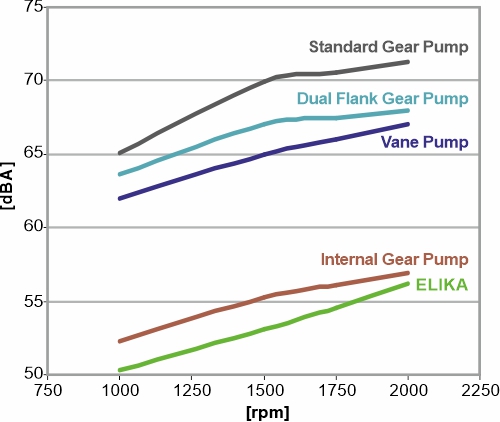

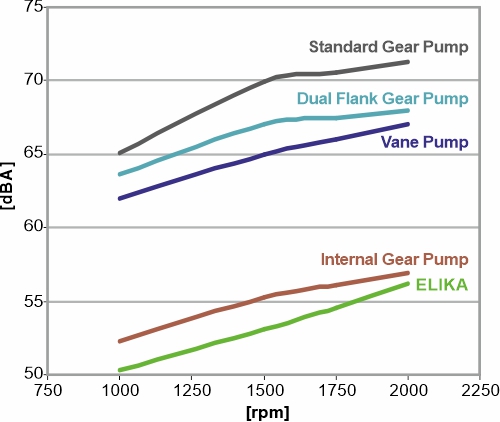

Noise comparison between:

standard external gear pump,

dual flank gear pump,

vane pump,

internal gear pump

and lowest of all the ELIKA helical gear pump

all at 200 bar pressure.

Noise reduction of this magnitude transforms noisy work environments into quieter, safer, and more productive spaces. This is particularly beneficial for industries where noise control is critical, such as medical equipment or energy sectors.

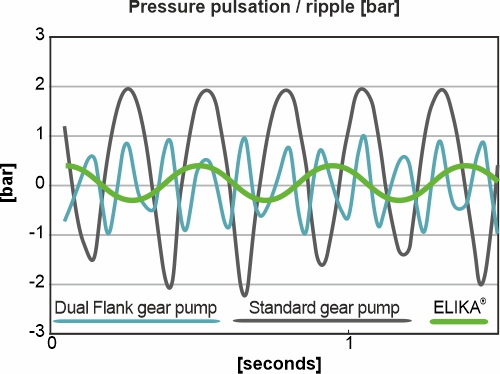

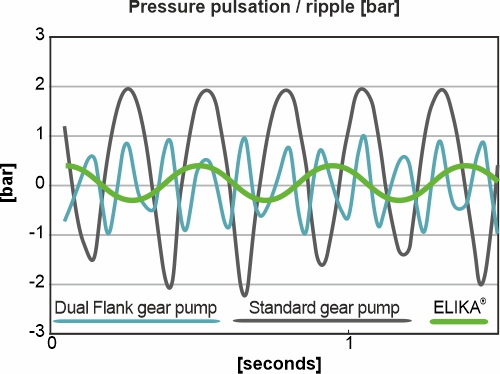

Reduced Pulsation and Vibration:

The pump’s helical gear design features a unique tooth profile which minimizes hydraulic pulsation. This design significantly reduces pressure oscillations, leading to less vibration. By minimsing pressure oscillations the Elika pump not only extends the life of your machinery but also enhances overall system reliability and performance.

The lower frequency of the ELIKA pump produces a quieter sound.

Pressure pulsation comparison between: standard external gear pump, dual flank gear pump

and the ELIKA helical gear pump.

Pressure 200 bar, rotation speed 1500 rpm.

The low pulsation reduces vibration in systems.

This results in less required investment in additional damping components.

Improved Efficiency at Low Speeds:

The Elika pump excels at maintaining high levels of efficiency, even at low operating speeds. This makes it ideal for applications that require low-speed operation, such as machinery that uses inverters or variable-speed drives. The pump’s high volumetric efficiency gets the most out of your hydraulic system, helping you cut down on energy consumption and reduce operational costs.

Technical Specifications. What Makes Elika Different?

The Elika gear pump's technical design is not just about quiet and efficient operation but also about superior performance across various applications.Below are some of the key specifications and advantages:

Noise Reduction:

The Elika pump can reduce noise by up to 15 dBA compared to traditional pumps, making it one of the quietest gear pumps available.

Pressure Capabilities:

The pump can reach working pressures of up to 300 bar, making it suitable for demanding hydraulic applications and ensures durability and performance within tough environments.

Unique Gear Tooth Profile:

The helical gear tooth profile is engineered to reduce noise and also minimize pressure oscillations. This ensures smooth operation and reduced vibration, contributing to the pump's longevity and reliability.

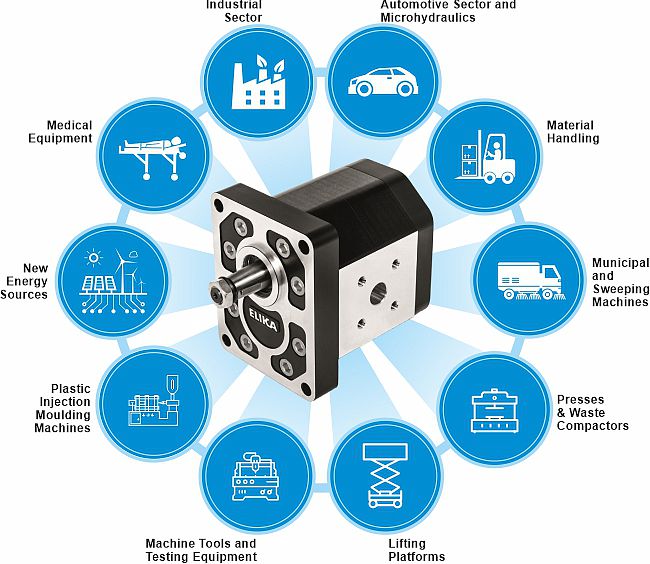

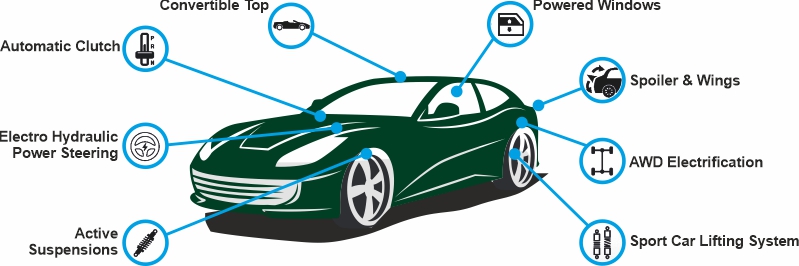

Application Flexibility:

Elika pumps are ideal for a range of industries and applications. Its high efficiency and low pulsation make it a versatile choice, particularly for those that require precision and reduced noise levels.

Multi-Configuration Options:

The Elika pump series offers a wide range of displacement options, from 2.1 cm³/rev to 199.8 cm³/rev, and allows for multiple pump combinations, with various industry standard flange and shaft options available.

Why Choose jbj Techniques for Elika Gear Pumps?

At jbj Techniques, we offer not only the Elika helical gear pump but also exceptional expertise in mechanical and fluid power solutions. With years of experience in hydraulic systems and a commitment to providing top-tier customer service, jbj Techniques is your go-to partner for upgrading your machinery with the latest in hydraulic pump technology.

Expert Advice:

We understand that every system is different, and our team is here to guide you through selecting the perfect pump configuration for your needs.

Tailored Solutions:

Whether you require a single or multiple section pump for large or small-scale operations, we offer solutions that meet your unique requirements.

Reliable Support:

We are dedicated to ensuring your machinery operates at its best. With a comprehensive range of spare parts available, you can trust jbj Techniques to keep your systems running smoothly and efficiently.

Ready to Upgrade Your Machinery?

If you're ready to experience the benefits of reduced noise, minimized vibration, and improved efficiency, it's time to consider the Elika helical gear pump. Visit our website www.jbj.co.uk to learn more about the product and how it can transform your operations. Our team is ready to assist you in selecting the right solution for your needs.

Contact us today!

Telephone:

01737 767493

Email:

info@jbj.co.uk