Ability to remove the seal and replace it without fully disconnecting or moving the mating flange or runs of pipework.

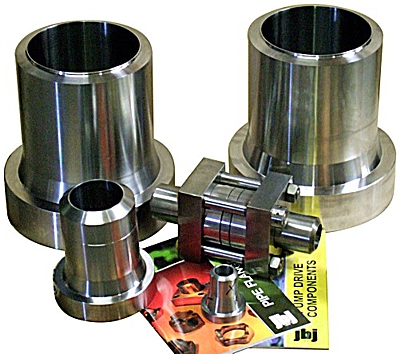

jbj Techniques manufactures and markets an innovative range of pipe flanges for fluid systems, designed for

» pressures up to 450 bar.

» flow rates up to 20,000 l.p.m.

» pipe sizes between 20 and 220 mm od.

They are specifically aimed at the steel, oil, gas, chemical, pharmaceutical, and food industries where ease of maintenance

features are economically particularly attractive, when downtime

must be kept to a minimum.

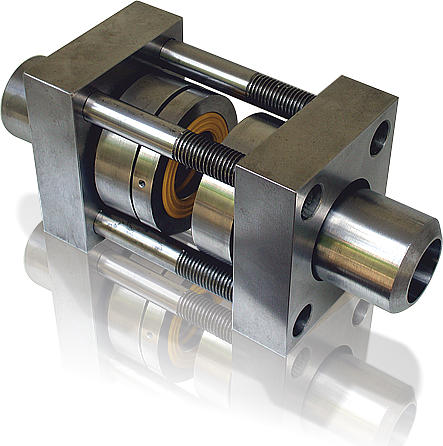

The ease of maintenance feature involves the ability to remove the seal, which is supported within a special retaining element, and replace it without fully disconnecting or moving the mating flange or runs of pipework as is typically the case with the standard DIN and CETOP flanges found in heavy pipework systems.

There are no comparable products at the high flow end of the range. The flange design has considerable commercial potential in areas where the cost of downtime is very high, such as in offshore industry.

The flange can be supplied in any steels to suit the environment including 080M15 (standard), stainless or exotic alloys.

As an alternative to tightening the flanges using traditional studs and nuts they can be supplied with a bolt tensioning system that utilizes a hand operated jacking system which enable pre-tensioning of two or more studs at one time, thus alleviating the need for large torque wrenches, spanners etc. which become a big problem when space is at a premium.