» Hydraulic Workholding on Machine Tools.

» Hydraulic Power Packs.

» Subsea R.O.V.’s.

» Press Applications.

» Pressure Die Casting Machines.

» Static and Impulse Testing Equipment.

» Stone Crushing Machines.

» Hydraulic Construction Tools.

» Demolition Tools.

» Quick Die Changing Equipment.

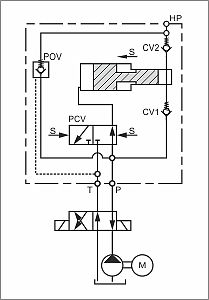

These pressure intensifiers are based on a piston principle, where a larger diameter piston pushes a smaller diameter piston, thus increasing the pressure to a factor equal to the ratio: Larger diameter area divided by smaller diameter area. The outlet pressure will always be proportionate to the supplied pressure.

Pilot operated check valves can be built in to allow high pressure side to be relieved through the intensifier.

The supplied flow and pressure to the MP-T are dependent on the intensification ratio chosen.

The table shows the flow and pressure for each model. Flow Q1 is when the pump pressure has been reached, and flow Q2 is moving up the vertical part of the curve (see graph left).

Please note flow values will vary with the viscosity of the fluid. Inlet values must not be exceeded.

Filtration of hydraulic media is essential due to the precise tolerances built into each quality unit.

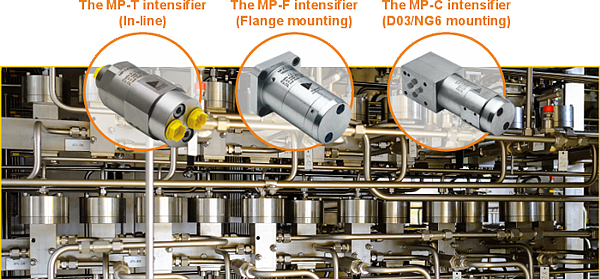

Compact hydraulic pressure intensifiers offer an easy, energy-saving, safe and cost-efficient solution to achieving a higher output pressure from an existing low-pressure power source. Low pressure supplied to the inlet port eg: 15 - 200 bar / 218 - 2,900 psi ~ is transformed to a higher pressure at the outlet port ~ from 20 - 4,000 bar / 290 - 58,000 psi. ScanWill’s pressure intensifiers are offered in cast iron and steel, with a chrome finish, as well as in stainless steel for the oil & gas sector.

The MP Series Hydraulic Pressure Intensifiers Increasing the Pressure in Production Lines

In large systems there can be problems maintaining the pressure for all functions, or a higher pressure is required for one function. Hydraulic pressure intensifiers can be inserted where needed ensuring sufficient pressure for all functions.