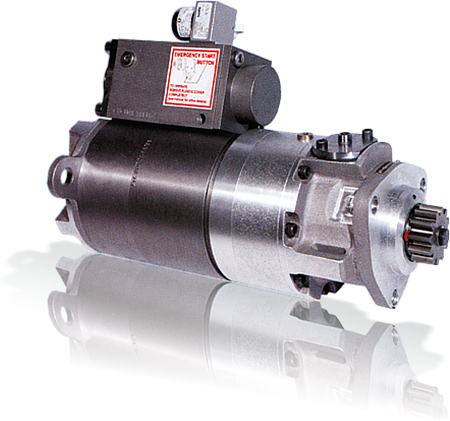

Pneumatic Starters

'Air' starters used to start up diesel engines & turbines.

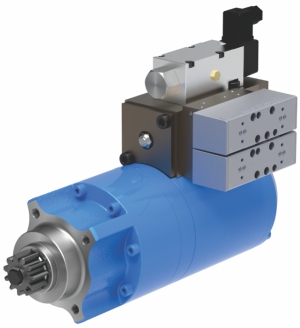

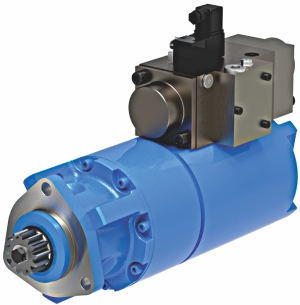

Addition of the HY-tact system to the standard starter ensures soft engagement of the pinion with the engine gear rim. This system ensures long life and reliability of the meshing gears. The start pinion is gently pushed out to meet the engine gear rim, if the pinion does not hit a tooth gap, it retracts and is rotated slightly ready for the next cycle. The cycle repeats until the pinion finds a gap and can move into full mesh, at this point, air is switched onto the starter to crank the engine.

ATEX certificated pneumatic starters are available depending on application. This would require the use of a bronze pinion which reduces life-span of the unit. The bronze option is obviously softer than the standard steel pinion.

Pilot valves for ATEX applications are different which requires a different setup with different valves but that is why we are here, to look at any application and put forward a solution to best achieve what is required.