These hydraulic gear motors feature versatility, strength and long useful life. Their simple construction ensures limited purchase costs and servicing.

Thanks to these basic concepts, together with ever-improving product design and features, research based on many years of experience, accuracy in material selection, production process followed in great detail and tests on mass-produced parts, Marzocchi hydraulic gear pumps and hydraulic gear motors have reached top quality standards.

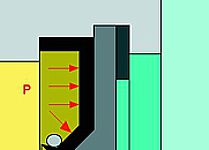

Marzocchi Pompe produce a system of radial sealing at the shaft that can bear enormous internal over-pressures without resulting in damage. This radial sealing is particularly useful in single direction hydraulic motors when, in certain conditions of use, high over-pressures will be generated at the motor output. With bi-directional motors, the area adjacent to the seal ring of the drive-shaft is maintained at atmospheric pressure by the drainage circuit. In single-direction motors, this area is directly connected to the output so any over-pressure impacts directly on the seal ring, causing the lip to turn over or the ring to be expelled from its seat with a consequent leakage of fluid.

These products can also be supplied complete with anti-cavitation valves. The motors are supplied with an internal drainage circuit. In this case the hydraulic motor always drains inside with a lower pressure; the combination of this product with a high-performance sealing ring substantially increases its reliability.

Marzocchi Pompe’s solution is made up of a single-lip radial seal ring in a Teflon™ composite material and reinforcement ring, both of which are the result of a special design and construction process.

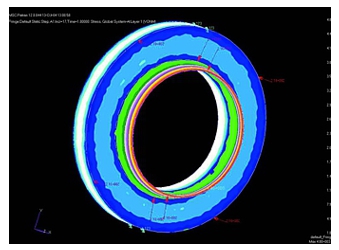

The external reinforcement ring fully follows the form of the seal ring, and has been sized to bear the axial force generated by internal over-pressures.

Before performing laboratory tests, it was necessary to strengthen the entire system that fastens the ring onto the flange, so that it could bear all the stresses submitted to the ring.

The best characteristics with respect to the components were determined with FEA software. The new radial seal ring has a much stiffer structure than normal rings, making it necessary to employ special assembly procedures.

The Teflon™ (P450) material adapts evenly to the texture of the machining on the shaft to guarantee a perfect seal.

Because of the internal pressure, the lip of the seal ring is constantly compressed against the shaft. The increase in pressure is accompanied by an increase in friction, with heat being generated in the sliding zone as a result.

The properties of the P450 material make it possible to bear high-pressure loads, strong friction and temperatures between -30 and +200ºC. To guarantee a long operating life, it was necessary to perform in-depth research on the methods for grinding the area where the sliding of the seal ring’s lip takes place.

Validation tests have revealed that the system is able to work on a continuous basis at a constant pressure of 30 bar (430 psi) without the spilling of fluid and without the ring and the shaft exhibiting wear. Tests performed at higher pressures also demonstrated the possibility of the system functioning for short periods of time (several minutes) with over-pressures of up to 140 bar (2,030 psi).

If the operating conditions must be maintained with extremely high over-pressure values (80-100 bar / 1,160 - 1,450 psi) for prolonged periods of time (over 30 minutes), the heat generated by the friction between the ring and the shaft can result in temperatures of over 300°C. This inevitably plays a part in deteriorating the structure of the P450 material used in the seal ring, as well as compromising the ground profile on the shaft, and thereby reduces its sealing function.

In the presence of pressure peaks, for example caused by errors of manoeuvre or an incorrect timing of the valves of the hydraulic circuit, or in static conditions, with the shaft immobile, this sealing system can bear over-pressures of over 210 bar (3,050 psi) without leading to any loss of fluid or deformation of the components.

The robust and reliable characteristics of this product make it particularly suitable for applications that function as appendages of other machines without knowledge of the exact circuit characteristics.

To ensure the efficiency of the seal ring under any operating condition, the surface finish or 'roughness' has to fall within a narrow set of values: to avoid burning, the course surface finish should not be too low (Ra > 0.2 ìm), while to avoid wearing down the lip of the seal ring too quickly, it should not exceed Ra.

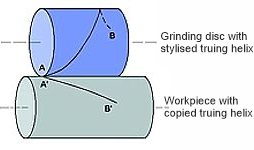

To optimise the sliding contact between the seal ring and the surface of the shaft, a special study was undertaken using a three-dimensional machine to control the REMOG surface. By means of a special software, it was possible to precisely identify the generating lines that the profile takes on according to the applied finish-grinding process.

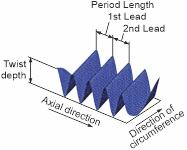

In addition to the roughness value, its shape is extremely important too. During the finish-grinding process, particular profiles are produced that may also have a helical direction on the surface of the shaft and could prevent the lip of the seal ring from retaining the fluid.

These profiles are initially generated while the grinding wheels are being sharpened. During the machining process, the impressions created on the grinding wheel as a result of sharpening are transferred to the surface of the piece being worked, resulting in a specific profile with preferential structure and relative roughness value.

The characteristics of these profiles therefore depend on the parameters used for sharpening the grinding wheel and for the machining process, such as the cutting speed, feed speed, type of lubricant and relative temperature.

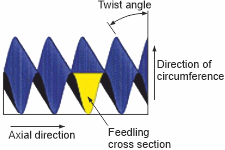

By making a three-dimensional analysis of the development of the ground surface, several important periodic parameters of the profile can be ascertained:

The number of threads: this depends on the ratio between the number of revolutions of the grinding wheel and that of the piece being worked (for example: if the grinding wheel speed is 1,200 rpm and the speed of the piece is 400 rpm, the number of threads will be 3).

The pitch: the axial distance between two corresponding peaks;

Groove depth: the vertical distance between the bottom and the peak of the roughness;

The transversal area of passage: the area between two consecutive peaks;

Helix angle: the angle formed between the direction of the helix and the radial direction at the axis of the shaft being worked.

An efficient sealing system requires the profile to be placed in such a way that the transversal areas of passage never communicate with the outside. This is possible if two conditions are met: the course surface finish or 'roughness' value must be between 0.2 to 0.3 ìm, and the profile produced by grinding must have a very narrow helix angle. As a result, there must be complete control of the production process, which, in addition to the type of material used, depends on the characteristics of machining, sharpening methods and final control of the conditions.

Defining the limits

At Marzocchi’s research and development laboratories, validation tests were conducted to verify the limits of the sealing system. These revealed that the system is able to work on a continuous basis at a constant pressure of 40 bar (580psi) without spilling of fluid and without the ring and the shaft noting wear.

Tests performed at higher pressures also demonstrated the possibility of its functioning for short periods of time (several minutes) with over-pressures up to 140 bar (2,030 psi).

If the operating conditions must be maintained with very high over-pressure values (80-100 bar/1,160-1,450 psi) for prolonged periods of time (over 30 minutes), the heat generated by the friction between the ring and the shaft can result in temperatures of over 300°C (570°F).

This inevitably plays a part in deteriorating the structure of the P450 material used in the seal ring as well as compromising the ground profile on the shaft, thereby reducing its sealing function.

In static conditions, with the shaft immobile, this sealing system can bear over-pressures of over 200 bar (2,900 psi) without leading to any loss of fluid or deformation of the components (a condition that can be verified on several pieces of machinery, where erroneously, the inlet and outlet pipes are inverted).

Pumps and gear motors are positive displacement components widely used in the design of hydraulic systems. Compact in size, they have a simple construction and are reliable, offering an excellent ratio between cost and performance.

Many applications suit the use of the single-direction hydraulic gear motor, which is of a construction similar to the hydraulic gear pump, but has very low starting torque, high transmitted torque, a wide range of operating speeds, very high efficiency and can be installed without the use of the drainage pipe.

The use of P450 in the radial seal of single-direction motors enables these parts to be safely used in heavy-duty applications, effectively protecting the sealing system on the shaft and preventing any fluid leakage helping to create hydraulic gear motors that can work at higher than normal pressures.

Marzocchi Pompe’s many years of experience with these types of products and its continuous development, design and testing, research into specific materials and sophisticated production techniques, assures the production of high quality components. Working together with jbj Techniques for over 40 years . . . an excellence in engineering!