Remove moisture and particles before entry to the system.

Moisture and particle accumulation are major factors of oil contamination in industrial equipment. Neglected, these detriments restrict equipment efficiency, causing machine downtime and significant expense in replacement oil, parts and repair labour.

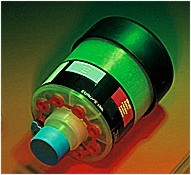

Hygroscopic breathers incorporate a proven, field tested design. They prevent water and contaminates from entering fluid reservoirs as differential pressures occur through thermal expansion and contraction of the fluid, or during the filling or emptying process.

Manufactured with a hygroscopic agent, they have the capability to extract water vapour from the air as it is drawn through the unit. Accompanying solid particles are then removed by a patented polyester fabric filter, allowing only clean, dry air to enter the system.

Change to these Hygroscopic Breathers for maximum machine performance.

These hygroscopic breather elements are state-of-the-art in design and function and are industry’s best choice for assuring maximum machine performance.

From DesCase-Europe: How do DESCASE desiccant filter help industry to reach targets in pollution prevention and sustainable development?

1. By increasing lubricant and mechanical components life:

By stopping solid particles from 0,5 micron and drying air, DESCASE desiccant filters optimize the lubricant and components life.

2. By Decreasing maintenance and failures costs:

Directly and indirectly, the DESCASE desiccant filters decrease replacement frequency for in line filters and lubricants and decrease the risk of failures (90% of failures are generated by a bad or polluted lubricant). In addition, because of the visual change indicator of the DESCASE desiccant filter, customers are immediately informed about a potential failure before having a shut down of the machine.

3. Through Improvement of energy consumption:

Because the DESCASE desiccant filters maintain and optimize the quality of the lubricant, efficiency of systems is optimized and that generate lower energy consumption. The energy consumption may be decreased by 20%.

4. By spending less money in waste treatment:

Because DESCASE desiccant filters customers will replace lubricants, in line filters and mechanical components less frequently they will spend less money in waste treatment. In addition of the financial profits generated for the plant it will help industry to protect environment.

In the field of desiccant filters for electrical transformers, you will generate 5 times less waste of chemical substances by replacing refillable desiccant filters with DES-CASE.

5. By protecting company managers:

DESCASE breathers are manufactured in accordance with European regulation including REACH (Registration, Evaluation, Authorization of Chemical substances). By preventing exposure of employees to harmful chemical substances, DESCASE breathers help prevent risk of criminal and civil liability (by stopping oil fumes generated by lubricated reservoirs and protecting the health of employees).