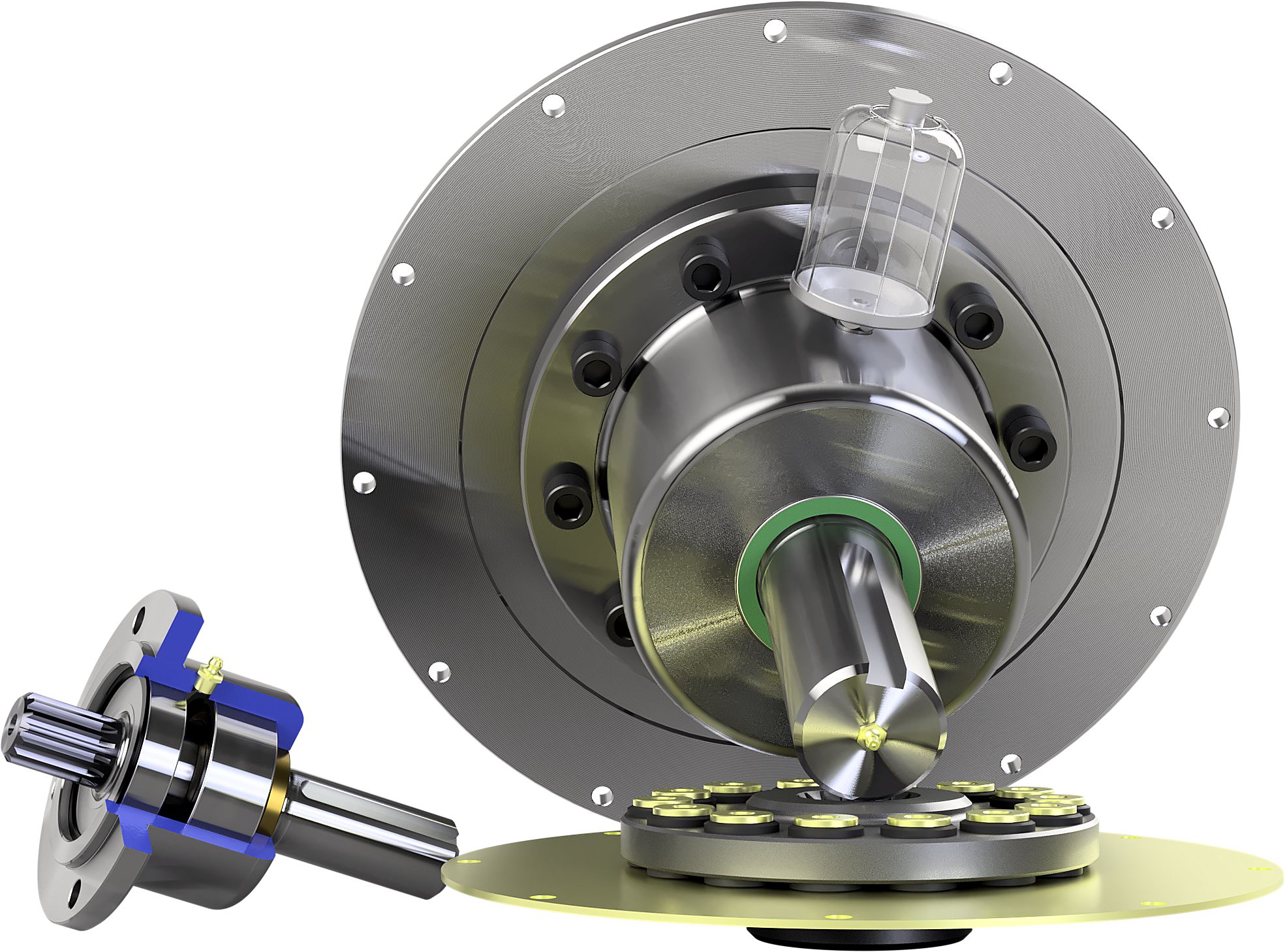

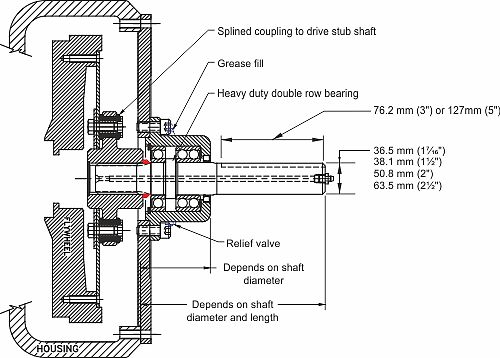

This stub shaft design employs a single and double roll radial ball bearing designed for light and heavy-duty work, not to exceed side loads listed in tables 1 to 4 on page 3 of the brochure link. The bearings are self-contained in our specially designed housing that will keep the assembly free of contamination. These supported stub shafts come pre-mounted to your specific flywheel housing plate or custom housing. The package includes a mounted bearing support and a flywheel coupling that will be sized to your application to drive the bearing support sub-assembly.

Specifically designed for side load applications.

Output: Depends on your application for shaft size and length.

Ratings:

Input torque (max.): 881 Nm (650 lb-ft).

Input / output speed: 3000 rpm.

Power (max.): 261 kW (350 HP).

Bearings: 3 years continuous running.