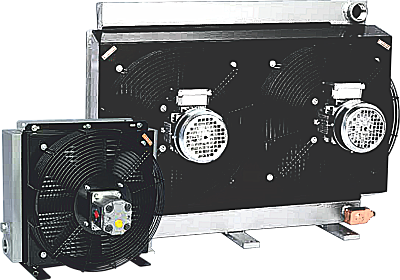

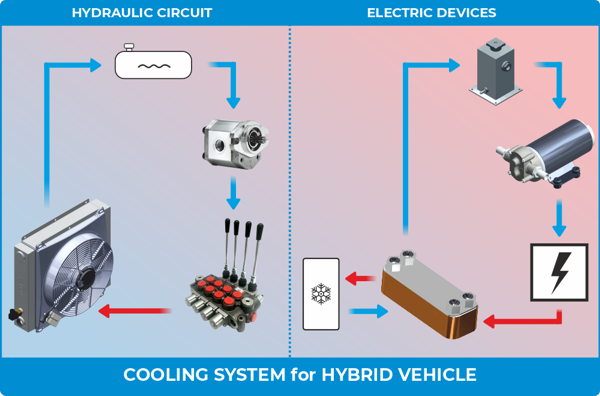

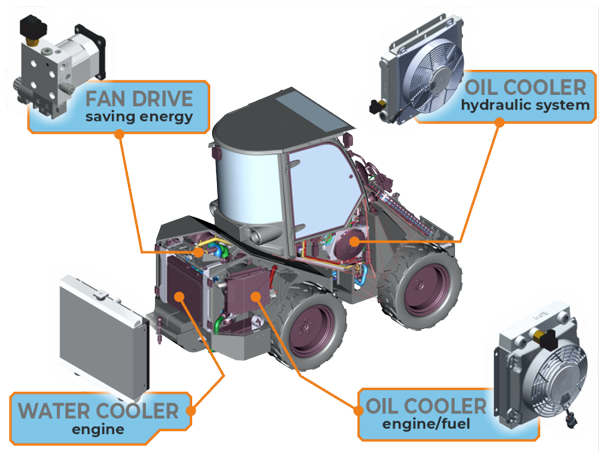

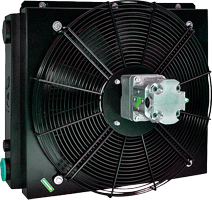

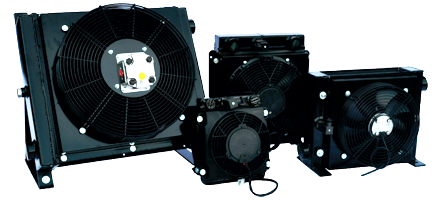

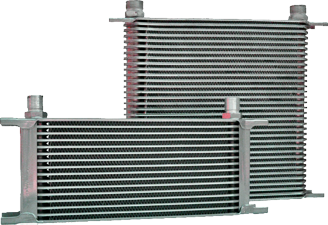

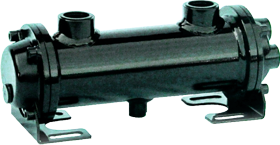

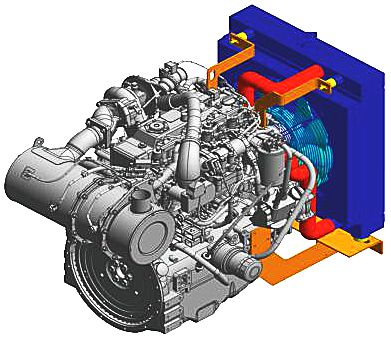

» Flexible cooling options: Air, oil, and water-based heat exchange solutions for a wide range of applications.

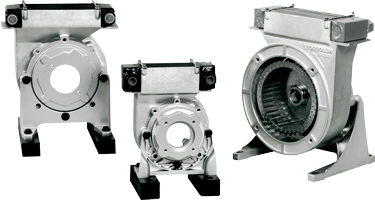

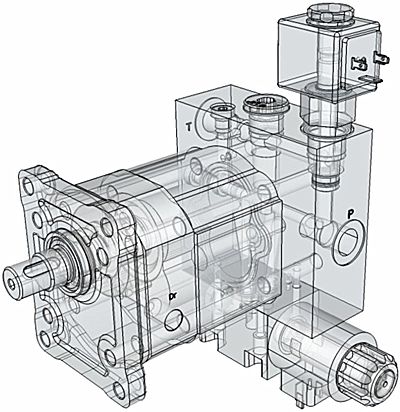

» Reduced downtime & maintenance: Improved thermal control protects seals, oil quality, and system components.

» Easy system integration: Designed to fit industry-standard layouts and existing machinery.

» Built for harsh environments: Proven materials and designs for demanding operating conditions.

» Expert engineering support: Help with sizing, selection, and application-specific requirements.