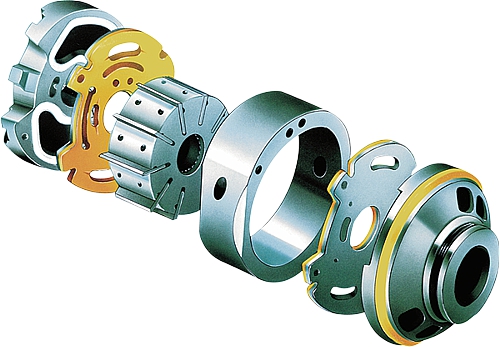

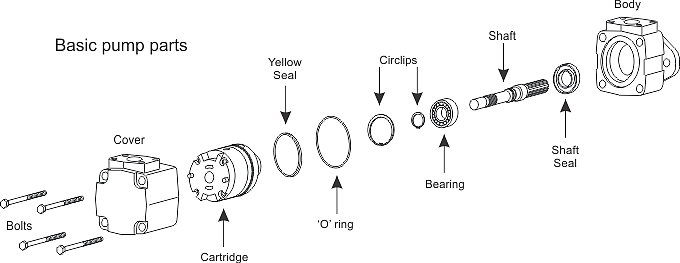

All the components subject to wear are contained in a cartridge unit that can be easily removed for inspection and/or replacement without disconnecting the pump from the circuit, drastically reducing expensive machine down time.

The cartridge contains a rotor, vanes and inserts, a cam ring and two covers.

During operation the rotor is driven by a splined shaft coupled to the drive unit. As the rotation speed increases, centrifugal forces, in combination with the pressure generated behind the vanes, push the vanes outwards, where they follow the profile of the cam of the ring with a sufficient contact pressure to ensure adequate hydraulic sealing.

The two opposed pumping chambers formed by the elliptical profile of the cam cancel out radial loads on the shaft bearings, thereby giving them extremely long lifetimes.

The versatility of the BV series pumps enables them to meet the requirements of the most varied industrial applications. In fact, as well as their proven high reliability and excellent volumetric efficiency in all working conditions, they operate with particularly low noise levels.

This is made possible by the special profile of the cam ring and the use of a 12 vane rotor that reduces the amplitude of the supply pressure pulses, thereby reducing induced vibrations.

Two opposed pumping chambers formed by the elliptical profile of the cam within the cartridge cancel out radial loads on the shaft bearings, thereby giving them extremely long lifetimes.

The special design of the double-lip vanes renders the BD series pumps particularly suitable for applications requiring high pressure levels and very low noise emissions.

» three versions of single pump (from 10 to 227 l/min at 1000 rpm)

» four versions of double pump (from 20 to 385 l/min at 1000 rpm), with input powers of over 328 kW at max pressure and speed.

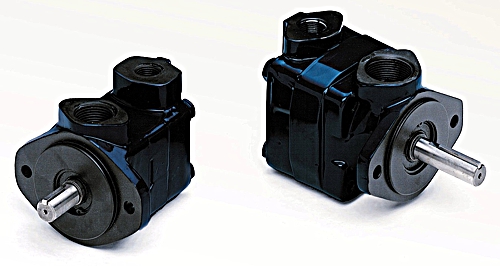

The BD series pumps are extremely compact and are supplied with SAE norm hydraulic flanges and shafts. This makes them very easy to install and guarantees their interchangeability with other similar pumps.

» Further details and technical information is available within

this catalogue.

The special design of the double-lip vanes renders the HD series pumps particularly suitable for applications requiring high pressure levels and very low noise emissions. Furthermore, the two opposed pumping chambers formed by the elliptical profile of the cam cancel out radial loads, dramatically reducing vibrations and considerably increasing the pump lifetime.

In addition to reliability, HD pump guarantees continuous high volumetric efficiency during its whole service time. That avoids having to compensate the typical efficiency loss of other kinds of pump, increasing the truck engine RPM, which causes higher fuel consumption and therefore air pollution. Such characteristics, along with an extremely low noise-level, make the HD pumps environmentally friendly, in line with the modern ecological demands.

» single pump (from 11 to 99 l/min at 1000 rpm)

» double pump (from 22 to 200 l/min at 1000 rpm) with maximum powers of over 126 kW at the max pressure and speed.

The pumps are extremely compact and are supplied with different types of either ISO or UNI norm mounting for the direct coupling with PTO and SAE norm hydraulic fittings. That, together with the capability to orientate the inlet and outlet ports, makes the HD pumps very easy to install and guarantees their interchangeability with other types of pumps.

Further details and technical information is available within

this catalogue

.

The versatility of the BV series pumps enables them to meet the requirements of a wide range of industrial applications. As well as their proven high reliability and excellent volumetric efficiency in all working conditions, they operate with particularly low noise levels.

This is made possible by the special profile of the cam ring and the use of a 12 vane rotor that reduces the amplitude of the supply pressure pulses, thereby reducing induced vibrations

In addition to reliability, HD pump guarantees continuous high volumetric efficiency during its whole service time. That avoids having to compensate the typical efficiency loss of other kinds of pump, increasing the truck engine RPM, which causes higher fuel consumption and therefore air pollution. Such characteristics, along with an extremely low noise-level, make the HD pumps environmentally friendly, in line with the modern ecological demands.

» four versions of single pump (from 8 to 230 l/min at 1200 rpm) and

» six versions of double pump (from 55 to 370 l/min at 1200 rpm), with maximum powers of over 223 kW.

The BV series pumps are extremely compact and are supplied with ISO norm mechanical couplings and SAE norm hydraulic fittings.

This makes them very easy to install and guarantees their interchangeability with other similar pumps.

Further details and technical information is available within

this catalogue

.

Particularly suited to applications in the mobile field. The special design of the flexible plates enables any thermal expansion in the rotor to be compensated for and to adequately cope with any sudden change in pressure.

Furthermore, the counter-pressure chambers positioned between the flexible plates and the cartridge covers balance the internal pressure; this ensures that the correct clearance between the rotor and the flexible plates is always maintained so guaranteeing maximum volumetric efficiency.

In addition to reliability, HD pump guarantees continuous high volumetric efficiency during its whole service time. That avoids having to compensate the typical efficiency loss of other kinds of pump, increasing the truck engine RPM, which causes higher fuel consumption and therefore air pollution. Such characteristics, along with an extremely low noise-level, make the HD pumps environmentally friendly, in line with the modern ecological demands.

» five versions of single pump (from 8 to 230 l/min at 1200 rpm) and

» seven versions of double pump (from 55 to 370 l/min at 1200 rpm), with maximum powers of over 223 kW.

The BV series pumps are extremely compact and are supplied with ISO norm mechanical couplings and SAE norm hydraulic fittings. This makes them very easy to install and guarantees their interchangeability with other similar pumps.

Further details and technical information is available within

this catalogue

.

Particularly suited to applications in the mobile field. The special design of the flexible plates enables any thermal expansion in the rotor to be compensated for and to adequately cope with any sudden change in pressure.

Furthermore, the counter-pressure chambers positioned between the flexible plates and the cartridge covers balance the internal pressure; this ensures that the correct clearance between the rotor and the flexible plates is always maintained so guaranteeing maximum volumetric efficiency.

The ten vane TQ type is particularly suitable for applications subject to sudden peaks of pressure, while the twelve vane TV model is specifically designed to meet very low noise requirements.

Fixed displacement vane pump, hydraulically balanced, with capacity determined by the type of cartridge used and the speed of rotation. The pump is available in five different displacements from 47 to 79 l/min at 1200 rpm and 7 bar.

Further details and technical information is available within

this catalogue

.

The special design of the inner flexible plates of the cartridge enables any thermal expansion in the rotor to be compensated for and to adequately cope with any sudden change in pressure.

The two opposed pumping chambers formed by the elliptical profile of the cam cancel out radial loads, dramatically reducing vibrations and considerably increasing the pump lifetime.

In addition to reliability, HQ pumps guarantee continuous high volumetric efficiency during their whole servicetime. That avoids having to compensate the typical efficiency loss of other kinds of pump which increase truck engine RPM, which causes higher fuel consumption and therefore air pollution.

Such characteristics, along with an extremely low noise-level, make the HQ pump environmentally friendly, in line with the modern ecological demands.

» 2 versions of single pump (from 39 to 88 l/min at 1000 rpm) and

» 2 versions of double pump (from 46 to 134 l/min at 1000 rpm) with maximum powers of over 103 kW.

The pumps are extremely compact and are supplied with different types of either ISO or UNI norm mounting for the direct coupling with PTO and SAE norm hydraulic fittings. That, together with the capability to orientate the inlet and outlet ports, interchangeability with other types of pumps.

Further details and technical information is available within

this catalogue

.

Versatility, reliability, high long-term volumetric efficiency and low noise level are the hallmark of the B1 and B2 series of vane pumps.

B1 and B2 pumps combine these qualities, with low running costs to offer a valid alternative to other types of pump for both and mobile use, particularly where noise level must be kept low.

B1 pumps are available in eight different versions (from 4.5 to 31.8 l/pm at 1200 rpm), with maximum power of up to 18 kW.

B2 pumps are available in seven different versions (from 27.27 to 59.09 l/pm at 1200 rpm), with maximum power of up to 27 kW.

Both are supplied with different mechanical and hydraulic connections, for extremely simple installation and complete interchangeability with other types of pump.

Further details and technical information is available within

this catalogue

.